Technical Specifications of Spring Shot Blasting Machine

Machine model: KBS-1085P/O37-2

Turbine Quantity and power: 2*37Kw

Loading capacity:200kg

Dust collector: Cartridge type HR24

Total power: Approx. 100Kw

Key Benefits of Spring Shot Blasting Machine

- The BlastKing’s Peening machines has lower production costs, this due to automatic operation, high output and uniform quality.

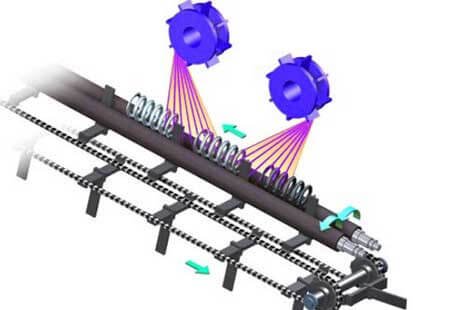

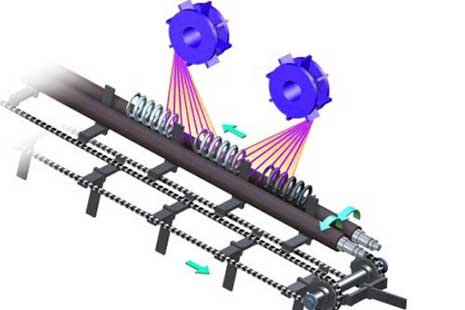

- The blasting turbines are high specific blast performance, parts are always shot peened in the hot spot of the blast stream, so the blast effect are optimied.

- The machines feature with High energy efficiency and high economy. Blast wheels fully exploit the energy applied and transform it to blast effect.

- The well proven separation system always maintains the shot operating mixture within the desired nominal size.

Features of Spring Shot Blasting Machine

Continuous throughfeed operation is simple, safe and ideally suited for fully automatic production.

Flexible loading / unloading concepts ideally meet user requirements.

Automatic systems with high performance and manufacturing consistency reduce production costs.

Adjustable dwell times and throughput speeds ensure process-safe, defined peening in uniform quality.

Applications of Spring Shot Blasting Machine

Shot peening machine are mainly used for shot peening suspension, valve and leaf springs.

Shot peening is a process specially designed to increase the fatigue strength of components subjected to alternating stress. It mainly improve the fatigue fracture and stress corrosion fracture resistance of the springs, and it also strengthened the reliability and durability of the springs.

Spring Shot Blasting Machine

Shot peening machine are mainly used for shot peening suspension, valve and leaf springs. The impact of the high velocity projectile stream on the surface of the spring causes the surface to produce a cyclic plastic strain layer, thereby causing a favorable change in the microstructure of the spring skin and introducing the skin into the residual compressive stress field.

Shot peening is a process specially designed to increase the fatigue strength of components subjected to alternating stress. It mainly improve the fatigue fractu

In the process of shot peening, the electrically controlled adjustable conveyor roller feeds the springs into the shot peening zone of the machine chamber, and the entire surface of the springs is exposed into the accelerated peening media, the high velocity abrasiv hits and rubs the surface of ssprings, so that the scale, rust layer and dirt are quickly detached, and the surface of the spring obtains a smooth surface with a certain roughness.

The Type G range is offered with through feed widths from 600mm to 3000mm. The blasting wheels are positioned vertically to the flow direction of the roller conveyor.BK 600, BK 1000 and BK 1500 are fitted with 4 shot blast wheels. The BK 2000 can be fitted with either 4 or 6 wheels. The bigger machines, BK 2500 and BK 3000, can be fitted with either 6 or 8 shot blast wheels. The 6 wheel version is used for treating plates or smaller profiles, whereas the 8 wheel version is mainly recommended for blasting profiles.

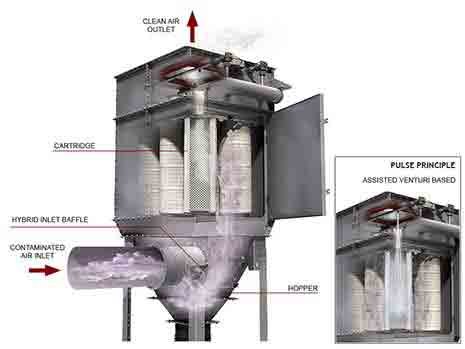

Cartridge Filter Unit

Each BlastKing machine is equipped with multiple cartridge filters. These filters are necessary to remove any impurities from the air used to blast resulting in a more even, direct, and effective blast.Benefits experienced with the BlastKing’ cartridge filters:

Large distance between folds in each cartridge filter leads to precise cleaning and better air pressure.

The impact separator within the cartridge filter unit ensures that the broken down fines are separated (which protects the filter cartridge against unnecessary wear).

The cartridge filters clean the cartridge automatically using an air pressure pulse, the intensity and duration of the pulse can be adjusted according to the type and amount of dust.

Pressure difference is monitored to automatically set the cleaning cycle increasing the life time of the cartridge and saves compressed air.

Easy exchange of cartridge filters.

Correct contact pressure.

Low compressed air consumption.

Constant cleaning, from top to bottom, due to conical design of the cartridge filter.

BlastKing ORICA Wheel

BlastKing group have the patented technology of the direct drive blasting turbine which motor power from 22kw to 75kw.

BlastKing Abrasive dosing unit

The abrasive dosing unit is abrasive flow control mechanism, The unit’s opening and closing angles can be controlled electrically or pneumatically. The abrasive flow rate is displayed on the ammeter of the electrical system. The unit adopts the German AGTOS abrasive dosing technology which use pneumatic controlling pull-type opening and closing technology.

References to spring shot blasting machine

Installation, Post-sales, Training & Safety

BlastKing Provide turnkey installation for the shot blaster. DIY installation by customer is also available according to the comprehensive documents, videos and drawings which provide by BlastKing, our engieers team also can provide real-time installation guidance.

The successful implementation of any blasting equipment is based upon the total commitment and dedication to the process. BlastKing’s field technicians are involved in the installation and training of the programmer and operator at the customer’s site or at BlastKing’s training facility. BlastKing has developed a complete program of maintenance training seminars. These are scheduled not only for new users but also for existing users. This structure is ideal for customers to send new employees so they can become more conversant with all BlastKing’s equipment.

Guarantee time of shot blasting machine will be one to five years. Technical support will be during the whole blasting machine life. Consumable spare parts will be supplied periodically.

All the equipment from BlastKing is conformity with CE&BV standard, and our factory have ISO9001, ISO14001 certification.

General emergency stop button is on all the BlastKing’s control panel. And sub emergency stop buttons are on conveyor systems. Detectors on the blast wheel covers, blasting chamber windows, elevators, separators will protect safety of the operators. Dust collection unit of shot blast machine dust emisssions is under 3mg/m3 which also bring dust free working environment.