Why Choose BlastKing

Hot Products

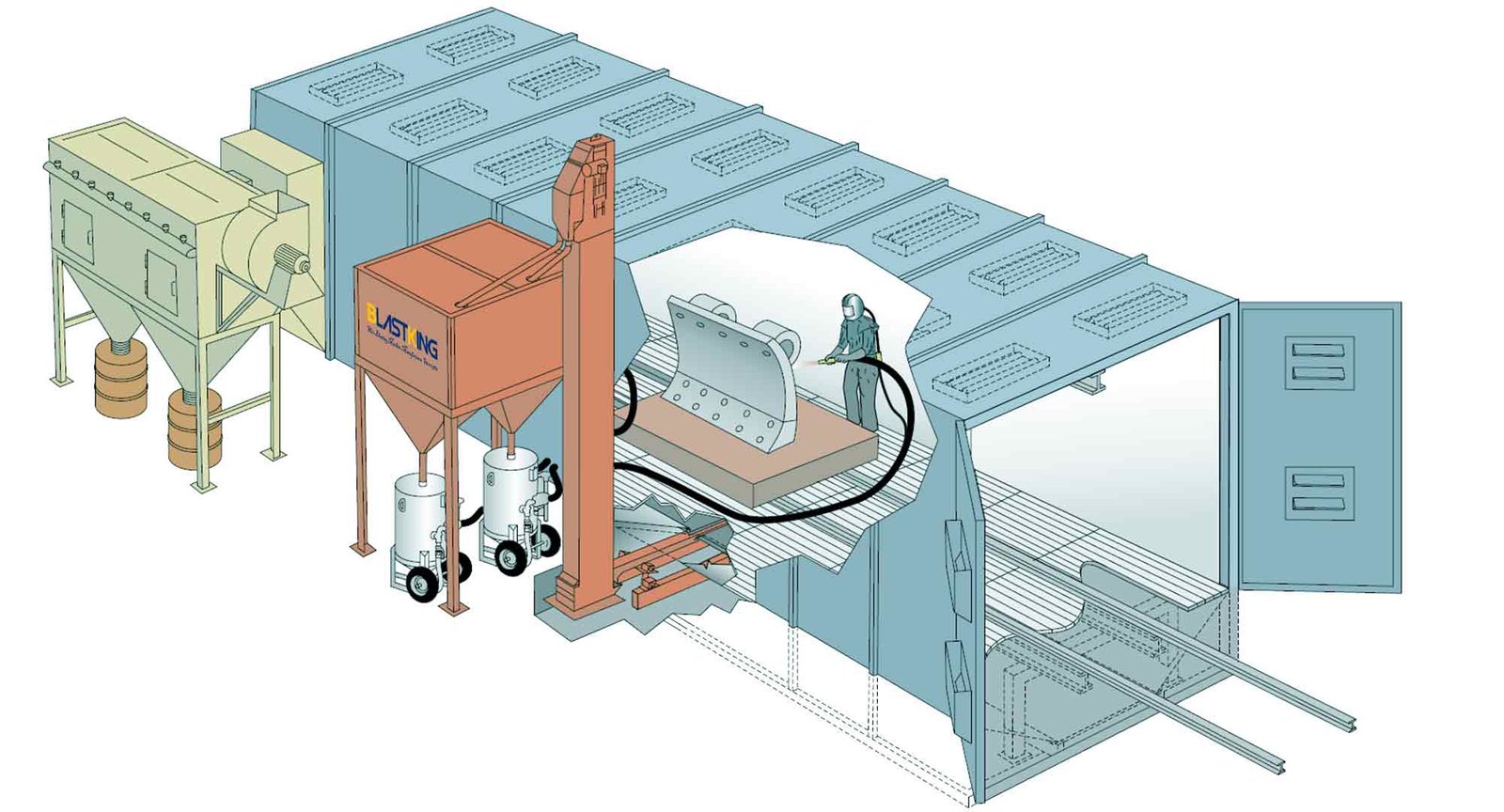

Revolutionize Your Workspace with Cutting-Edge Airblast Equipment Solutions!

Struggling with air quality issues affecting your team’s well-being? Take a deep breath as our airblast equipment clears the air, promoting a healthier and more productive atmosphere.

Explore how our advanced air blast and wet blast technology not only cleans but also purifies the air, creating a workspace where safety and well-being go hand in hand.

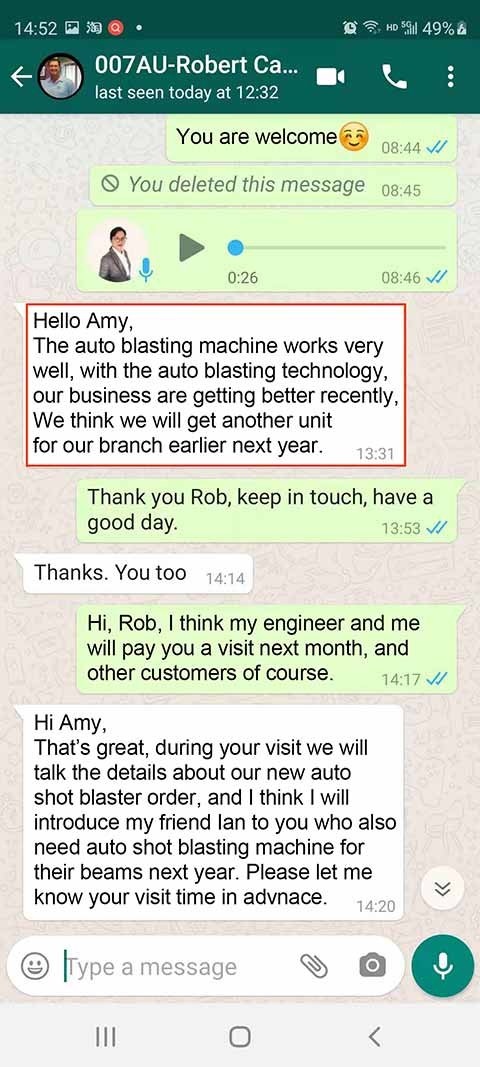

Innovative Technology, Proven Results

Is downtime costing you money? Are traditional methods falling short on quality? Do you desire a solution that’s both swift and sophisticated?

Discover the seamless blend of efficiency and elegance with our airblast equipment. Elevate your space while minimizing downtime.

Call us today at +86 135 8931 7685

Estimated Manufacturing And Shipping Times

Design and manufacturing time

We understand the urgency of your projects. That’s why our commitment to excellence extends beyond just quality—it’s about delivering cutting-edge air blast equipment and wet blast equipment swiftly to meet your tight deadlines.

Ready for Production from Day One

At BlastKing, we believe in going the extra mile to ensure your experience with our air blast equipment and wet blast equipment is seamless and efficient. That’s why all our machinery undergoes a meticulous installation and commissioning process right here at our state-of-the-art factory before it reaches your doorstep.

Ensuring Safe Arrival, Every Time

At BlastKing, we understand the significance of your investment in air blast and wet blast equipment. That’s why we take every measure to guarantee that your machinery arrives not only in top-notch condition but also ready for immediate deployment. Our commitment to excellence extends to the meticulous packing of every component before it embarks on its journey to your facility.

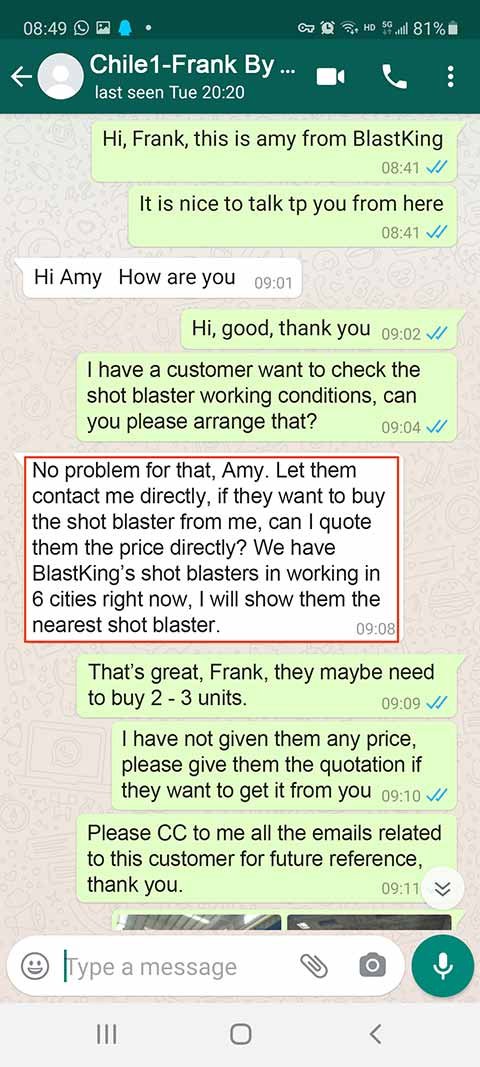

Your Success, Our Priority!

FAQs (Frequently Asked Questions)

BlastKing has the most extensive portfolio of airblast equipment. It includes manual airblast equipment for blast cleaning through to highly complex peening machines for the aerospace industry.

The extensive experience within the global technology centres for airblast equipment means BlastKing has the biggest competence pool in this field.

Don’t Miss Out on the Future of Manufacturing. Act Now!

Is downtime costing you money? Are traditional methods falling short on quality? Do you desire a solution that’s both swift and sophisticated?

Revolutionize your processes, elevate your quality standards, and witness unparalleled success. Contact us today to embark on a transformative journey toward manufacturing excellence.

Call us today at +86 135 8931 7685

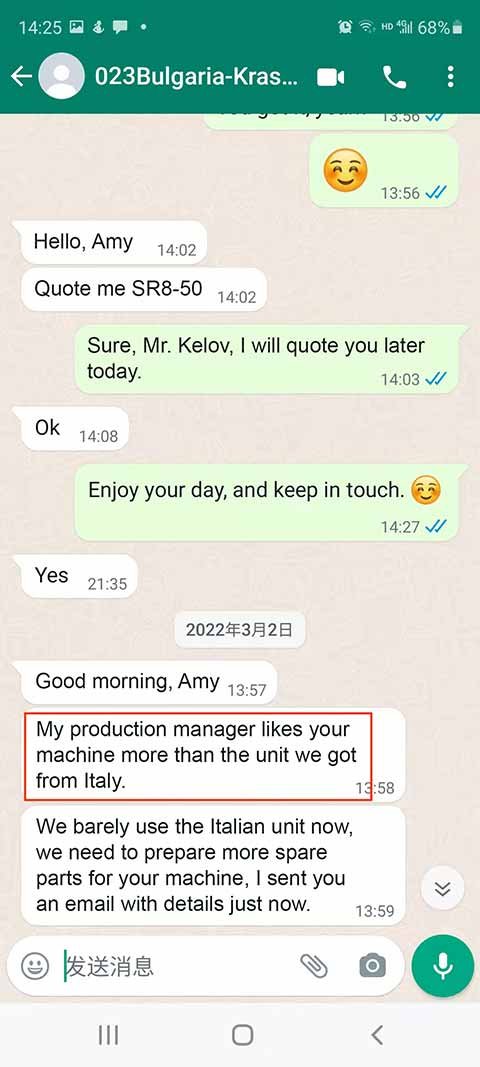

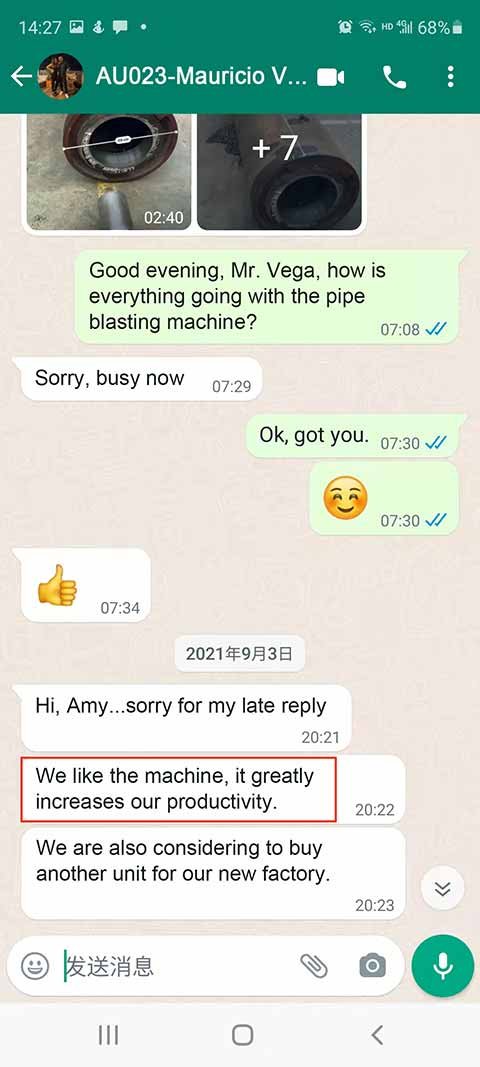

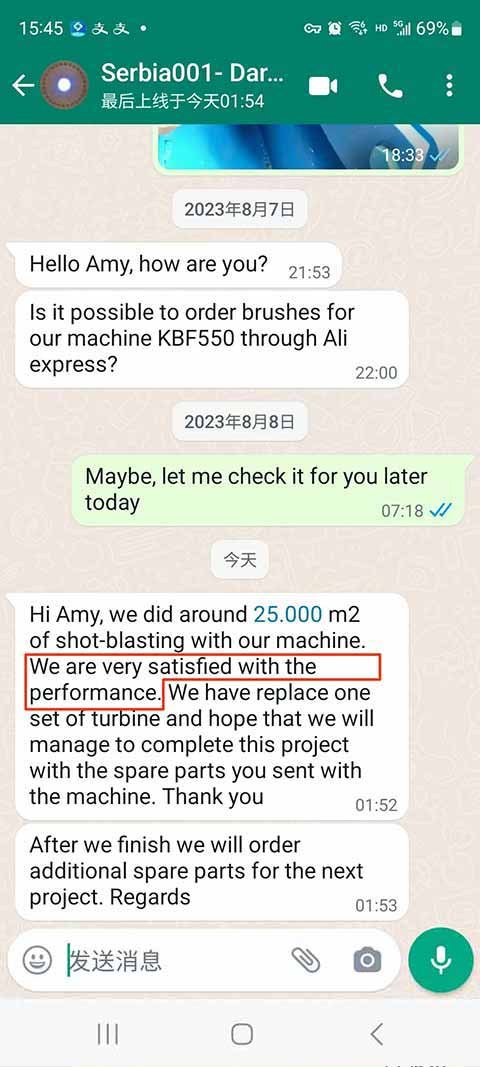

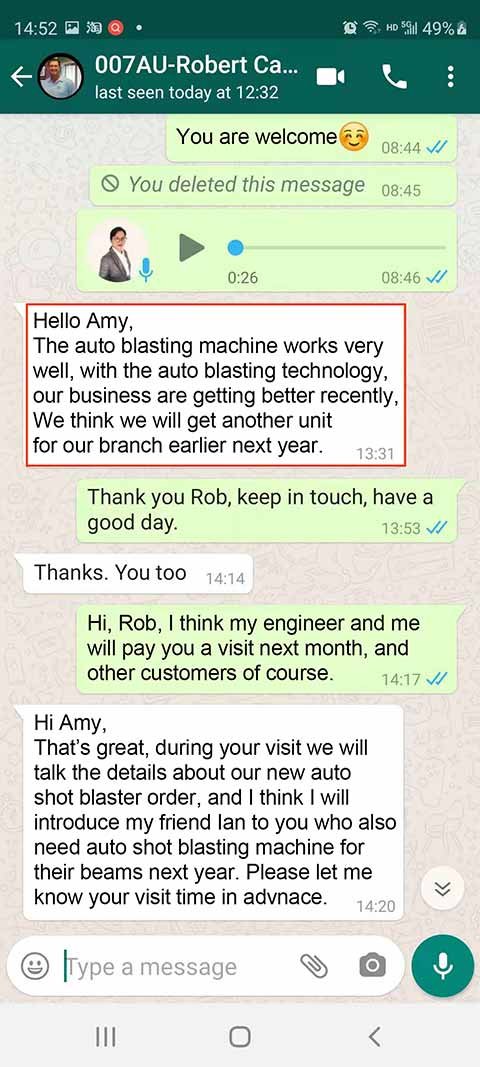

We deliver results