Technical Specifications

| Type | ZH850L | ZH1100LA | ZH1412L |

|---|---|---|---|

| mold size (mm) | 850×850 | 1100×1100 | 1200×1400 |

| space between molds (mm) | 390-790 | 400-800 | max. molds thicknesss 850 |

| mold-assembling stroke (mm) | 400 | 400 | 600 |

| max. shooting range(mm) | 690×580 | 850×950 | 1100×1250 |

| max. core weight(kg) | 30 | 40 | 80 |

| drive mode | hydraulic | hydraulic | hydraulic |

- The technical data is not binding and may be subject to change.

Depending on the type of parts, production method, etc., further machine types and measurement specification sheets upon request.

Applications

BlastKing’s core shooting machine has three kinds of process versions: coated sand hot box, cold box, and hot & cold type (the parameters are different, the contents of this technical file are related to the hot box process).

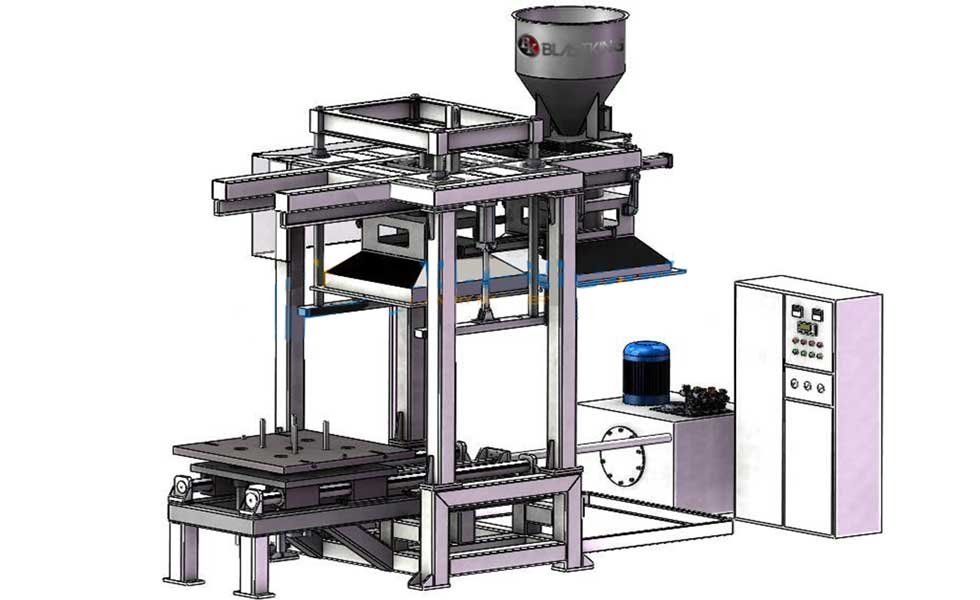

ZH-L Type Core Shooting Machine

ZH-L horizontal split core shooting machine adopts PLC automatic programming control, horizontal open mold, top surface sand shooting design, can make sand or sand core of various sizes. The machine has the functions of the upper core and the lower core. After the sand (core) is solidified, the top core is worked at the same time as the mold is opened to ensure that the sand mold (core) falls off the lower mold. After the mold is completely opened, the lower mold of the machine is removed by itself to the outside of the machine body, the lower core operates to lift the sand core (core) for easy core handling. This machine can be used as a cold core box core shooting machine or as a hot core box core shooting machine. The cold core machine is equipped with a triethylamine generator.

The main driving systems of the ZH-L core shooting machine are hydraulic type, such as the opening and closing of the ZH-L core shooting machine mold, removing of the lower mold, the upper pushing of core and the lower pushing of core (sand shooting and crushing sharing), etc. The working pressure of the equipment is adjustable to ensure the stable and reliable function of the whole machine.

References to Core Shooting Machine

Installation, Post-sales, Training & Safety

BlastKing Provide turnkey installation for the core shooting machine. DIY installation by customer is also available according to the comprehensive documents, videos and drawings which provide by BlastKing, our engieers team also can provide real-time installation guidance.

The successful implementation of any blasting equipment is based upon the total commitment and dedication to the process. BlastKing’s field technicians are involved in the installation and training of the programmer and operator at the customer’s site or at BlastKing’s training facility. BlastKing has developed a complete program of maintenance training seminars. These are scheduled not only for new users but also for existing users. This structure is ideal for customers to send new employees so they can become more conversant with all BlastKing’s equipment.

Guarantee time of core shooting machine will be one to five years. Technical support will be during the whole machine life. Consumable spare parts will be supplied periodically.

All the equipment from BlastKing is conformity with CE&BV standard, and our factory have ISO9001, ISO14001 certification.

We will answer your email shortly!

Have questions or need help? We’re here to help you. Whether you are inquiring about a quote/order, seeking sales or site assistance, technical support or for general inquiries you’ve come to the right place. If you wish to contact BlastKing Group by email, please fill out the requested information below in order for us to better serve you.