Basic Specification for Profiles Beams Shot Blaster

| Type | KB 1500HD | KB 2000HD | KB 2500HD | KB 3000HD | KB 4000HD |

|---|---|---|---|---|---|

| Machine entrance width (mm) | 1600 | 2100 | 2700 | 3200 | 4200 |

| Machine entrance height (mm) | 550 | 550 | 550 | 550 | 550 |

| Work speed (m/min) | 0.5-2.3 | 0.5-2.4 | 0.5-2.3 | 0.5-2.5 | 0.5-3.0 |

| Number of blast wheels | 4 | 6 | 6 | 6 | 8 |

| Power per blast wheel (kW) | 11/15 | 11/15 | 11/15 | 11/15 | 11/15 |

| Roller pitch (mm) | 800 | 650 | 650 | 800 | 800 |

| Alternative pitch (mm) | tailored by customer | tailored by customer | tailored by customer | tailored by customer | tailored by customer |

Application to Profiles Beams Shot Blaster

Surface Preparation: Beams, metal sheets, pipes/tubes, slabs, welding constructions

Smoothing: Pickled or eroded surfaces, machining lines, etc.

Decorative Blasting: Light metals, stainless steel, copper, brass, etc.

Peening: Parts exposed to high stress, torsion bars, etc.

De-burring: Flame cut, sawed and stamped parts

Key Benefits for Profiles Beams Shot Blaster

Key Benefits for Profiles Beams Shot Blaster HD Type

- Demonstrates the highest performance variants of this machine type for blasting sheet metal and profiles

- Used where high through feed speeds and longer maintenance intervals are necessary

- Blasts between 5 and 20% quicker due to a special wheel arrangement

- Particularly useful for integration into fully automatic production lines

Features for Profiles Beams Shot Blaster HD Type

- Integrated filter unit possible – depends on machine size

- Even very thick plates can be blasted due to a higher loading capacity of the rollers

- Perfect lining and special roller track for a long life time of the machine

Profiles Beams Shot Blaster HD Type Instruction

Profiles Beams Shot Blaster HD Type demonstrates the highest performance variants of this machine type for blasting sheet metal, H beams, and variety profiles.

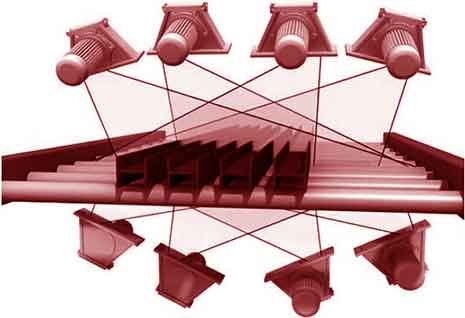

The main difference of this machine to others offered in the marketplace is the angled arrangement of the shot blast wheels on the top of the machine. This arrangement reduces the build up of abrasive on the sections of longer profiles. By using this method a significantly larger percentage of the blasting energy is used on the main task, i.e. de-rusting and scale removal from sheet metal and profiles, and avoids creating piles of abrasive.

The HD profiles and beams shot blast machines with angled wheels blasts between 5 and 20% quicker than a roller conveyor with shot blast wheels that are installed straight.

HD roller conveyors are used where high through-feed speeds and longer maintenance intervals are necessary.

The HD roller conveyor machine with angled wheels blasts between 5 and 20% quicker than a roller conveyor with shot blast wheels that are installed straight.

HD roller conveyors are used where high through-feed speeds and longer maintenance intervals are necessary.

This machine is particularly useful for integration into fully automatic production lines, and is suitable for shot blasting sheet metal as well as profiles.

Shot Blasting Cabinet and Abrasive Removal Unit

As with all BlastKing roller conveyors Blast Machines the shot blasting cabinet liner is manufactured completely from high manganese. High manganese has a property which is hard enough to deal with the shot blasting from 35HRC to more than 60HRC. They are attached from the outside and are easy to replace. When aggressive shot is used, additional lining of high manganese, tool steel or cast material can be provided.

To avoid shot leakage, several rubber layers or curtains are fitted in areas of heavy wear. These are mounted in a V-Track and are easy to replace.After the blasting process, the workpiece may still be in blast media, which must be cleaned off. This task is carried out by a rotating brush and a high blow off station.

The brush is fitted with securely attached brush segments, which are interchangeable.To avoid blast media building up on long parts, the rotation brushes remove the spent abrasive from the workpieces surface into a specially designed trough which has a screw conveyor taking the media back into circulation. To keep the position between the brushes and the screw conveyor constant when blasting different sized work pieces, both are built with the same adjustable framework. Finally any remaining media on the work pieces will be removed by the blow off station, which is mounted on the same framework and uses high pressure ventilators to blow off any media remaining.

BlastKing ORICA Blast Turbine

BlastKing group have the patented technology of the direct drive blasting turbine which motor power from 22kw to 75kw.

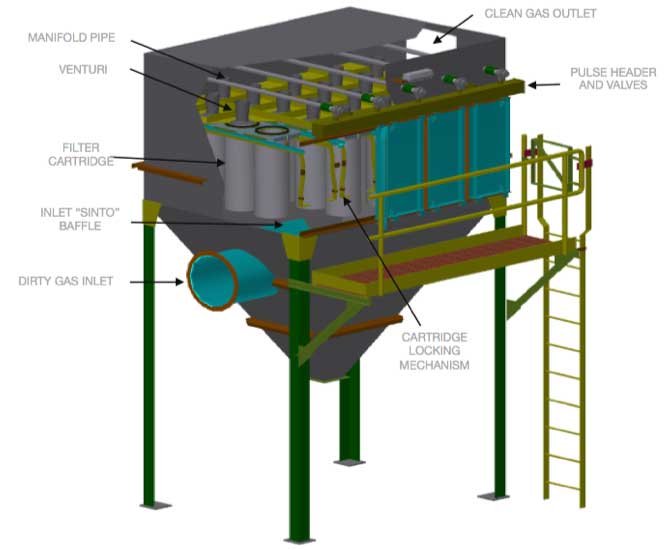

Cartridge Filter Unit

Each BlastKing machine is equipped with multiple cartridge filters. Above all these filters are necessary to remove any impurities from the air used to blast resulting in a more even, direct, and effective blast.

To sum up, benefits experienced with the BlastKing’ cartridge filters:

- Large distance between folds in each cartridge filter leads to precise cleaning and better air pressure.

- Most importantly, the impact separator within the cartridge filter unit ensures that the broken down fines are separated (which protects the filter cartridge against unnecessary wear).

- And easy exchange of cartridge filters.

- Further, correct contact pressure.

- Moreover, low compressed air consumption.

- In addition, constant cleaning, from top to bottom, due to conical design of the cartridge filter.

Installation, After-sale, Training & Safety

BlastKing Provide turnkey installation for the shot blaster. But DIY installation by customer is also available according to the comprehensive documents, videos and drawings which provide by BlastKing. Furthermore, our engieers team also can provide real-time installation guidance.

The successful implementation of any blasting equipment is based upon the total commitment and dedication to the process. Thus BlastKing’s field technicians are involved in the installation and training of the programmer and operator at the customer’s site or at BlastKing’s training facility. At the same time, BlastKing has developed a complete program of maintenance training seminars. Above all, these are just scheduled not only for new users but also for existing users. In short, This structure is ideal for customers to send new employees so they can become more conversant with all BlastKing’s equipment.

Guarantee time of shot blasting machine will be one to five years. Most importantly, technical support will be during the whole blasting machine life. In addition, consumable spare parts will be supplied periodically.

All the equipment from BlastKing is conformity with CE&BV standard, and our factory have ISO9001, ISO14001 certification.

General emergency stop button is on all the BlastKing’s control panel. And sub emergency stop buttons are on conveyor systems. Moreover, detectors on the blast wheel covers, blasting chamber windows, elevators, separators will protect safety of the operators. Further, dust collection unit of shot blast machine dust emisssions is under 3mg/m3 which also bring dust free working environment.