Technical Specifications of Paver Blocks Shot Blaster

| Machine Model | KBC600 | KBC800 | KBC1000 | KBC1200 | KBC1500 |

|---|---|---|---|---|---|

| Max. working width (mm) | 600 | 800 | 1000 | 1200 | 1500 |

| Max. working height (mm) | 400 | 400 | 400 | 400 | 400 |

| Working speed (m/min) | 0.5~6 | 0.5~6 | 0.5~6 | 0.5~6 | 0.5~6 |

| Top wheels×power(kw) | 2×7.5/11/15 | 2×7.5/11/15 | 2×7.5/11/15 | 2×7.5/11/15 | 2×7.5/11/15 |

| Optional lateral wheels×power(kw) | 1×7.5/11/15 | 1×7.5/11/15 | 1×7.5/11/15 | 1×7.5/11/15 | 1×7.5/11/15 |

| Foundation pit required | None | None | None | None | None |

- The technical data is not binding and may be subject to change.

Depending on the type of parts, production method, etc., further machine types and measurement specification sheets upon request.

Key Benefits of Paver Blocks Shot Blaster

- Whilst lowering your cost per part, high values can be added to your concrete products due to the consistent, uniform quality finish achieved at high process speed.

Features

The adjustable blast wheels provide a very uniform surface result, even at high speeds

This is assured by smooth/stepless speed control, electro-pneumatic dosage regulation and optimal blast wheel positioning

Furthermore, the use of hardened tool steel for the blast wheel wear parts assures a long service life

Applications of Paver Blocks Shot Blaster

Surface texturing of concrete products like:

- Blocks

- Slabs

- Kerbstones

- castings…and more

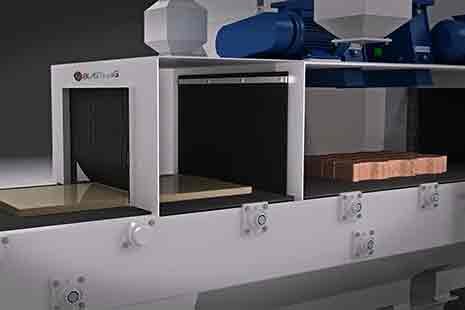

Rubber Belt Paver Blocks Shot Blaster

BlastKing rubber belt Paver Blocks Shot Blaster perform efficient and high quality blasting of concrete products like blocks, slabs and kerbstones.the shot blasting machine can be easily integrated into the concrete block/interlock block layers production line, The shotblasting machine for concrete/interlock block layers that can handle maximum product width of 1000mm and 1200mm.

The advantage: the blast process creates a unique character of the blocks, with a high quality surface appearance, which in turn creates added value to the product.

The number and the position of the blast wheels can change depending on the geometry and on the work pieces (in some cases it is requested only the blasting of the upper side, in some other cases also of the lateral side). Loading and unloading of the work pieces on the conveyor can be done manually or through automatic clamps.

With proper regulated control and type of shot used in the shot blast machine, it is possible to produce different surface finishes to produce “antique” effect on marble stones and “bush-hamering” effect on cement products.

High Quality Blasting and Efficiency

The flexible design and control of the machine provides the optimum blasting process for various concrete products. This is most important as concrete is a delicate material: to ensure the desired finish / appearance is achieved, the blast pattern must be uniform, and the patterns from different wheels should not overlap.

Blow-off Station

Stainless steel shot is the preferred abrasive for concrete/stone applications. After blasting, a blow-off station with a high pressure blower removes the shot from the surface of the concrete blocks/stone. The nozzles are adjustable in height and therefore adaptable for the treatment of different concrete block/stone sizes.

Shot Blasting Cabinet

The blasting chamber is fabricated by high strengthened steel plates and profile steel which ensures adequate intensity and rigidity of the machine. ,blast wheels layout adopt 3-D dynamic simulation design, which ensures optimal shot blasting angle and distance.

As with all BlastKing Blast Machines adopt easy replaceable high manganese steel guard liner on hot blasting zone, which is hard enough to deal with the shot blasting hardness up to 60HRC. The overlapped liner blocks are installed inside the blasting chamber which eliminate any possibility that the high speed blasting media will hit the blasting chamber directly.

High impact toughness can make full use of the reflection kinetic energy of shot to continue to blast cleaning the surface of work piece, so greatly enhance the cleaning efficiency and quality.

High chrome wear resistant perforated saddle plate are deployed at the bottom of the blasting chamber which ensure the used blasting media will appropriately get into the abrasive recycle system and prevent any damages to the bottom screw conveyor.

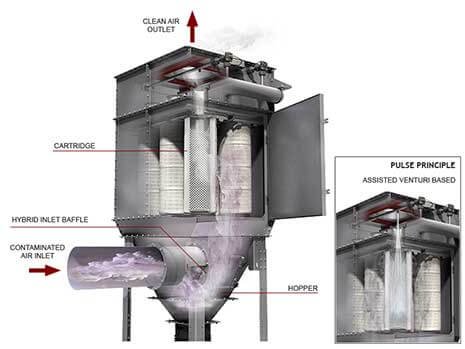

Cartridge Filter Unit

Each BlastKing machine is equipped with multiple cartridge filters. These filters are necessary to remove any impurities from the air used to blast resulting in a more even, direct, and effective blast.Benefits experienced with the BlastKing’ cartridge filters:

Large distance between folds in each cartridge filter leads to precise cleaning and better air pressure.

The impact separator within the cartridge filter unit ensures that the broken down fines are separated (which protects the filter cartridge against unnecessary wear).

The cartridge filters clean the cartridge automatically using an air pressure pulse, the intensity and duration of the pulse can be adjusted according to the type and amount of dust.

Pressure difference is monitored to automatically set the cleaning cycle increasing the life time of the cartridge and saves compressed air.

Easy exchange of cartridge filters.

Correct contact pressure.

Low compressed air consumption.

Constant cleaning, from top to bottom, due to conical design of the cartridge filter.

BlastKing ORICA Wheel

BlastKing group have the patented technology of the direct drive blasting turbine which motor power from 7.5kw to 75kw.

References to Paver Blocks Shot Blaster

Installation, Post-sales, Training & Safety

BlastKing Provide turnkey installation for the shot blaster. DIY installation by customer is also available according to the comprehensive documents, videos and drawings which provide by BlastKing, our engieers team also can provide real-time installation guidance.

The successful implementation of any blasting equipment is based upon the total commitment and dedication to the process. BlastKing’s field technicians are involved in the installation and training of the programmer and operator at the customer’s site or at BlastKing’s training facility. BlastKing has developed a complete program of maintenance training seminars. These are scheduled not only for new users but also for existing users. This structure is ideal for customers to send new employees so they can become more conversant with all BlastKing’s equipment.

Guarantee time of shot blasting machine will be one to five years. Technical support will be during the whole blasting machine life. Consumable spare parts will be supplied periodically.

All the equipment from BlastKing is conformity with CE&BV standard, and our factory have ISO9001, ISO14001 certification.

General emergency stop button is on all the BlastKing’s control panel. And sub emergency stop buttons are on conveyor systems. Detectors on the blast wheel covers, blasting chamber windows, elevators, separators will protect safety of the operators. Dust collection unit of shot blast machine dust emisssions is under 3mg/m3 which also bring dust free working environment.