Introduction to Automated Sand Blasting Machine?

Surface preparation is the unsung hero behind every smooth, long-lasting finish. Traditional sand blasting is effective—but also labor-intensive, time-consuming, and loaded with safety risks. Meet the next generation of surface preparation: Automated Sand Blasting Machines that drastically reduce labor, improve precision, and slash production time.

What Are Automated Sand Blasters?

Automated sand blasters are advanced systems designed to clean, smooth, or texture surfaces using high-pressure streams of abrasive materials. These machines are programmed to handle repetitive tasks with precision, minimizing human intervention.

Elevate Your Surface Preparation with BlastKing’s Cutting-Edge Technology

Key Advantages of Automated Sand Blasting Machines

- Higher Efficiency

These machines work around the clock like dedicated night owls. They’ll blast through large batches without breaking a sweat. - Precise Results

If you’re tired of lopsided finishes or missed spots, automated systems deliver consistent blasting patterns. They’re a bit like a pastry chef who always decorates the perfect cupcake swirl. - Safer Working Conditions

Nobody wants to wear a sand storm as a new fashion statement. With automation, operators can keep a safe distance and let the machine handle the dusty business. - Lower Costs in the Long Run

Upfront expenses can be steep, but it’s akin to buying a good coffee maker. You spend a bit more at the start, then save on all those expensive café trips down the road. - Broad Range of Uses

Whether you’re stripping paint off a vintage car or prepping aerospace components for a fresh coating, these systems adapt to many jobs without batting an eyelash.

Don’t Let Outdated Methods Erode Your Reputation and Revenue

Types of Automated Sand Blasters

- Pass-Through / Inline Conveyor Sand Blasters

So you’ve got parts that need thorough blasting on all sides—top, bottom, and maybe even the edges? No problem. There are multiple conveyor setups designed to hustle your items through the blasting zone, giving them the exposure they need at each angle. It’s like sending your parts on a well-choreographed tour, where they exit looking crisp and ready for whatever comes next.

Depending on shape and size, these conveyors can pair with different nozzle arrangements. Some nozzles remain in one fixed spot, while others oscillate up, down, or side to side for broader coverage. In certain cases, they even mount on a spinning head or link up with a robotic arm that maneuvers each nozzle precisely where it’s needed. It’s a bit like having a dance troupe of nozzles, each hitting its marks in perfect harmony.

- Roller Conveyor Automated sand blasting machine

Imagine being able to clean or prepare just about any flat, curved, or oddly shaped item—all on one conveyor line. That’s what these conveyor sand blaster machines are all about. They handle everything from stainless steel sheets, glass panels, stone panels, concrete pavers, and baking trays to toaster shells, computer cases, and decorative signs. If you’ve got a non-stick pan that’s lost its magic or a metal profile that needs a fresh start, these systems tackle the job without batting an eyelash.

Think of it like having your own personal clean-up crew, except they don’t take coffee breaks or complain about dusty work. Whether you’re working with aluminum sheets, electric iron bottoms, or even a stray DVD panel, the conveyor sand blaster powers through each piece, smoothing and polishing in record time. So if you’ve ever been stuck wondering how to restore or prep all those weirdly shaped items for painting or coating, these machines have your back. It’s the perfect way to keep your operation efficient—no matter how quirky your parts might be.

- Automated blasting machine for Molds

Ever feel like you’re locked in a wrestling match with big, oddly shaped molds? Our Molds Automated Air Blasting Machines are here to give you the upper hand. They tackle round, oval, square, disc, and other tricky forms without breaking a sweat. Whether you’re dealing with aluminum extrusion dies, forming die molds, automobile tire molds, plastic or rubber molds, or even large and medium chassis, these machines come prepared. They’ll also handle decorative parts or communication equipment. Basically, if you’ve got a mold that needs cleaning, these systems are ready to roll. It’s time to stop dreading mold cleanup and let the machine do the heavy lifting.

- Continuous Rotary Table Automated sand blasting machine

Indexing turntables have long been essential in manufacturing for precise workpiece positioning and repeatable blast coverage.

They can be loaded and unloaded either manually or through automated robotics, aligning with different production needs.

BlastKing’s standard and custom platforms handle a wide range of workpiece sizes.

Configurations vary from 2 to 24 rotating stations for full surface exposure during the blasting cycle.

Accurate turntable positioning and rotating part stations ensure consistent, thorough results.

Nozzle setups include stationary, linear, and robotic options for targeted cleaning.

Up to 16 blast guns can oscillate vertically and horizontally while stations rotate, achieving complete coverage in one pass.

These systems are used for discs, cylinders, square parts, handicrafts, glass shades, non-stick pans, flashlights, baking pans, stainless steel basins, and communication equipment.

Eight vertically oscillating guns handle side and skirt areas of pistons, while horizontally sweeping guns clean tops and interiors.

- Table Automated Abrasive Blasting Machine

Ever felt like you’re juggling a bunch of odd-shaped parts, each needing a thorough sandblast? A Rotary Table Blaster is your backstage assistant—spinning everything in front of the blast stream so you don’t have to. It handles small batches of various shapes and sizes without missing a beat.

Key Advantages

- Low Initial Cost: It won’t break the bank, making it a solid choice for tighter budgets.

- Small Footprint: Fits easily in your shop, leaving room to walk around (or dance if you like).

- Simple Operation: It’s as easy as loading parts, setting a timer, and hitting “go.”

- Batch-Friendly: Throw in several items at once and watch them rotate through the blasting zone together.

- Fully Automated: Adjust the speed and blasting duration. When time’s up, it stops—no guesswork, no worries.

- Low Maintenance: Fewer headaches, more time to focus on other tasks.

- User-Friendly Panel: Switch between auto and manual modes with a flick of a button.

What It’s Great For

This machine works wonders on thermosetting plastics—like compression and injection molding, bakelite, and resin. It’s designed to polish the edges or surfaces of these products without overdoing it. If you’ve ever worried about blasting a part into oblivion, relax. The machine’s timer ensures it won’t blast longer than you set.

Give a Rotary Table Blaster a try if you want a small, straightforward, and budget-friendly system that gracefully handles batches of parts—kind of like a round dance floor where every piece gets its turn in the spotlight. If you can load it, you can blast it!

Unmatched Quality and Durability in Every Machine

- Basket Automated Blasters

Tumbling Basket Automatic Sand Blaster: A Friendly Workhorse for Bulk Surface Finishing

Ever wish you could toss a heap of small parts into a machine, press a button, and magically have them come out deburred and evenly blasted? That’s exactly what the tumbling basket automatic sand blaster does. Picture a rotating drum inside a sealed chamber, with a sandblasting gun fixed in place, spraying away as the basket spins like a merry-go-round at the fair.

How It Works

The tumbler (or drum) inside the chamber rotates, allowing each and every part to take its turn under the blasting gun. The system includes timed stops, automatic sandblasting, and alert functions—like a personal assistant that knows when to clock in and clock out. You can also run one or both sandblasting guns at once, so if your workload suddenly doubles, the machine is more than happy to pick up the slack.

Loading and unloading parts is a breeze. If you ever need to switch to manual mode, you can remove the tumbler and add an operator platform, transforming this whiz-bang contraption into a standard enclosed manual sandblaster. Think of it as having two machines in one—it adapts faster than a chameleon.

Uses and Applications

This machine is a master at handling medium and small parts en masse. It loves everything from Bakelite or plastic pieces to screws, small metal parts, and cast items. Need a matte finish on aluminum or copper? No problem. It also blasts hardware automotive parts, nails, screwdrivers, and even electronics. Imagine tossing in a handful of Bodhi nuts or bracelets—yes, it can clean those too without breaking a sweat.

Whether you’re dealing with regular metal bits or spiritual beads, this machine doesn’t judge. It simply gets the job done, ensuring a smooth and even finish. So if you’ve got a pile of parts that need some TLC, this friendly tumbling basket system is ready to roll. Literally.

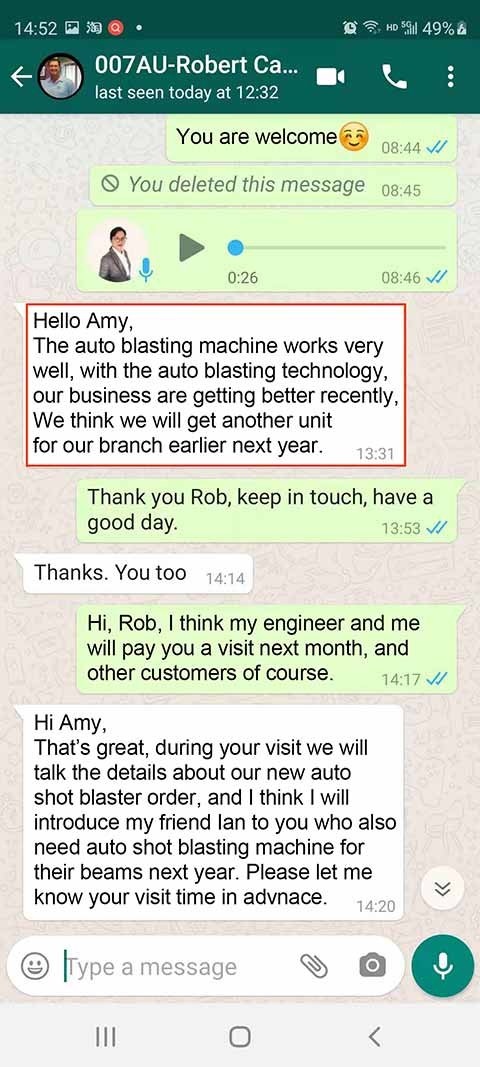

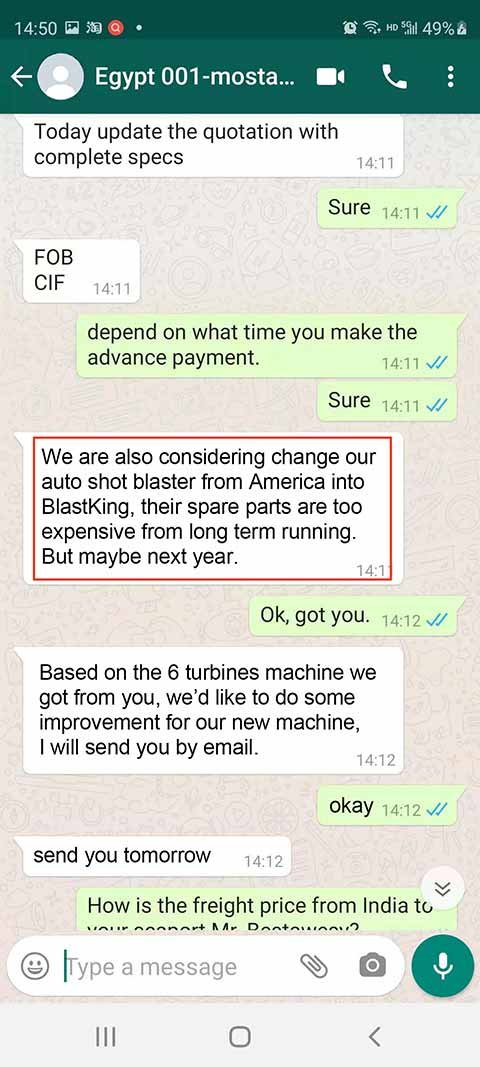

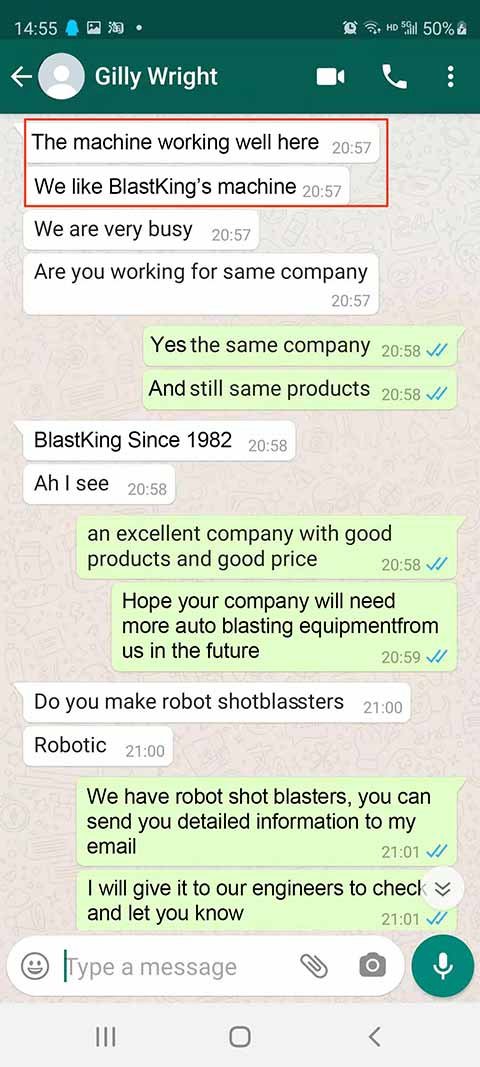

Global Support and Service You Can Rely On

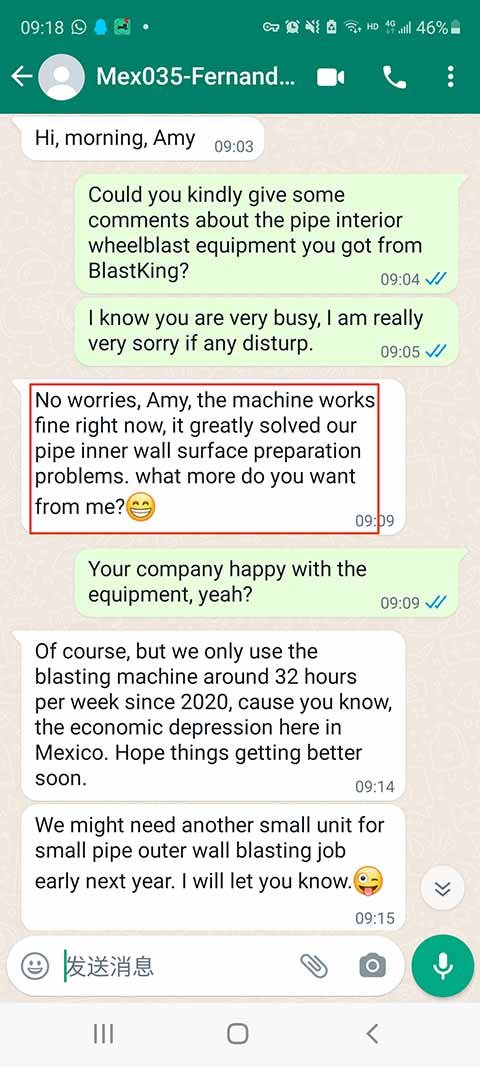

- Cylinder and Pipe Blaster

Let’s face it: scrubbing cylinders, pipes, or any other round-shaped workpieces can feel like trying to polish a basketball with a toothbrush. That’s where Cylinder and Pipe Blasters step in. They automate the entire sandblasting process, making life easier for anyone who needs spotless, corrosion-free surfaces.

Typical Tasks

- Pipe cleaning

- Surface preparation

- Descaling

- Corrosion removal

How It Works

First, you set your cylinder onto rubberized drive rollers, close the door, and start the blast cycle. While the piece rolls on these drive rollers, oscillating nozzles mounted on a shaft move back and forth, covering every bit of the exterior.

If you need to blast the inside too, an optional nozzle slides in and cleans that interior surface. Some models handle tubes from ¾ inch all the way up to 60 inches in diameter, so whether you’re working with skinny pipes or jumbo barrels, there’s a setup ready to tackle it.

It’s kind of like giving your cylinder a full-body spa treatment, inside and out, without you lifting more than a finger. The result? Smooth surfaces that are ready for painting, coating, or whatever else comes next in your workflow.

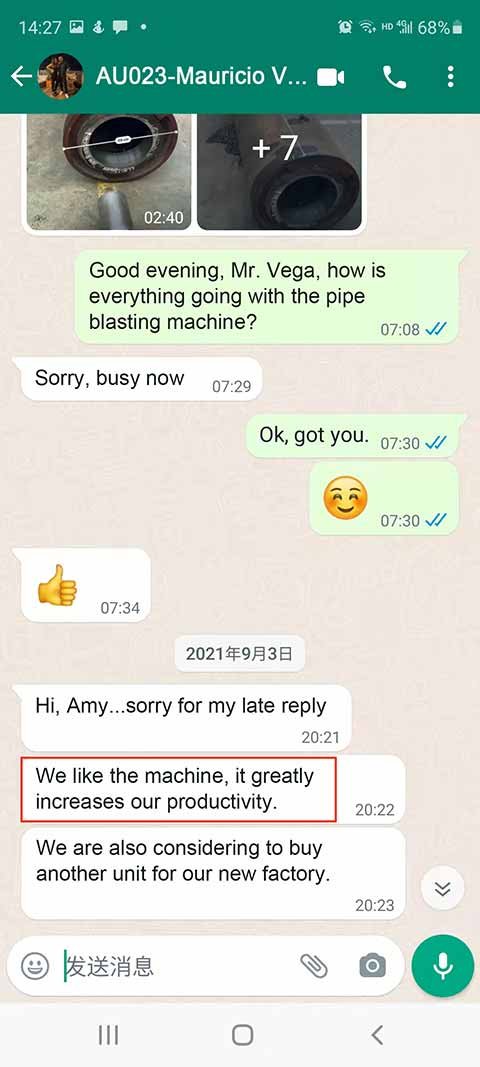

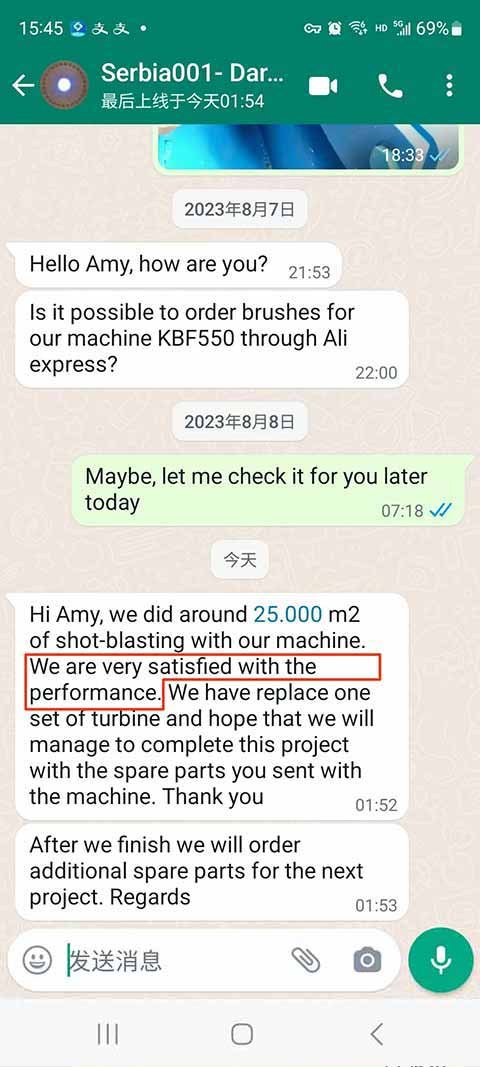

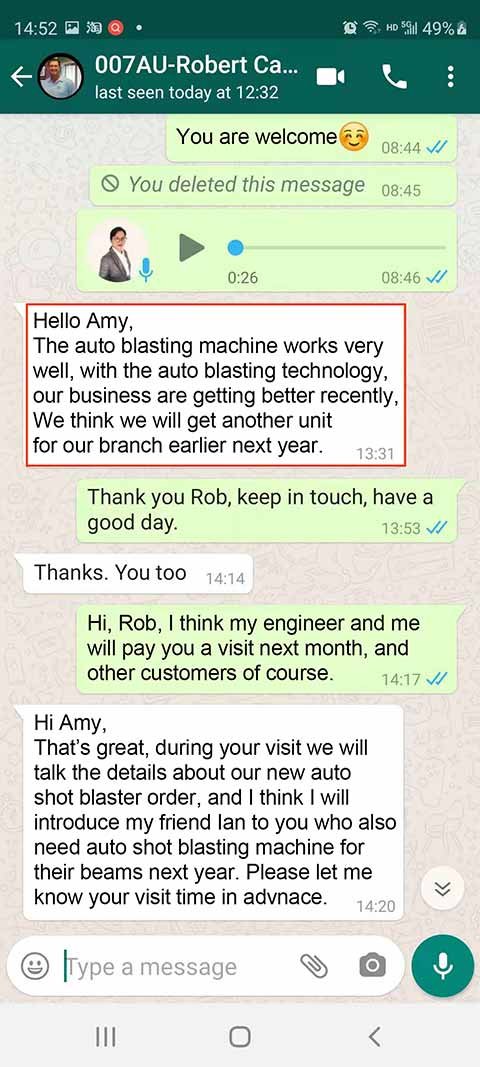

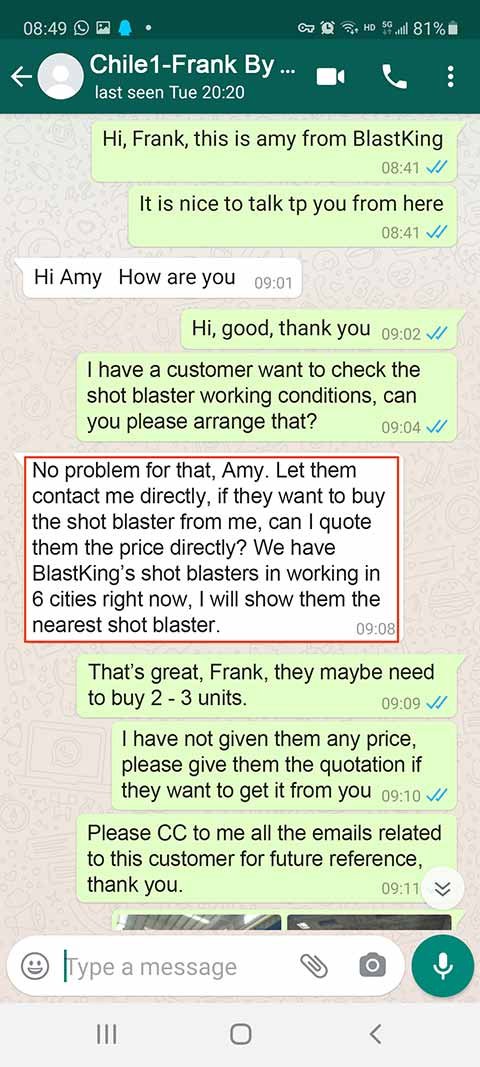

Join Over 5,000 Satisfied Customers Worldwide

- Custom Automated Abrasive Blaster Systems

Ever feel like your parts don’t fit the “one-size-fits-all” mold? You’re not alone. BlastKing offers Abrasive Custom Automated Sand Blasting Machine systems that adapt to your specific production goals—no square-pegs-in-round-holes nonsense. We look at every angle: the size, weight, and shape of your parts, how many you need to blast each hour, and even how you’ll move them around your shop floor. Think of it like tailoring a suit, but for your manufacturing process.

If you’re working with giant, heavy items or small, delicate pieces, BlastKing can engineer a solution that suits your workflow to a T. It’s a bit like having your own personal problem-solver who never says, “That’s impossible!”—instead, they say, “Let’s make it happen.” And we do.

Tailored Blasting Solutions for Every Industry Need

Other Alternative Automated Blasting Machine Options

Need more power and speed than standard air blast machines can offer? No worries—BlastKing has you covered. We provide a full lineup of wheel blast machines that crank up productivity to a whole new level. If you’ve been testing automated air blast systems and they’re just not hitting the mark, consider taking our wheel blast solutions for a spin. It might be the upgrade your surface preparation process is craving, like switching from a family sedan to a race car. Go ahead, give our automated wheel blast machines a look—you might just thank yourself later.

Innovative Technology, Proven Results

Is downtime costing you money? Are traditional methods falling short on quality? Do you desire a solution that’s both swift and sophisticated?

Discover the seamless blend of efficiency and elegance with our airblast and wheelblast equipment. Elevate your space while minimizing downtime.

Call us today at +86 135 8931 7685

We deliver results