A blast room gives you a controlled space for abrasive blasting. Instead of blasting outdoors, you blast inside an enclosed room, so dust stays contained. As a result, you keep your shop cleaner, protect operators, and improve surface quality.

At BlastKing, we design and build blast rooms around your part size, your daily output, and your abrasive type. In addition, we match the recovery floor and dust collector to your workflow. Share your basic details, and we will send a layout and a clear quote.

So you get:

-

Cleaner work areas and better visibility

-

Lower abrasive cost with recovery and recycling

-

Faster throughput with a smoother workflow

-

More stable results for coating and painting

1. What is a Sand Blast Room?

A sand blast room is an enclosed workspace for sandblasting or shot blasting. First, the operator blasts inside the room. Then, the room contains dust and abrasive media. Therefore, you get a cleaner process and more consistent results.

A complete system includes:

-

abrasive storage and feed

-

blasting pots, hoses, and nozzles

-

ventilation and a dust collector

-

abrasive recovery and an abrasive cleaner (when you reuse media)

Turbocharge Your Productivity in the Blasting Room

2. Main Features of a Performance Blast Room

A high-performance blast room uses five core systems. Next, you can choose options based on your output goal.

A) Chamber Design

The chamber holds the blasting work. So, we build it strong and easy to use. We add:

-

secure doors and seals

-

wear protection where abrasive hits

-

bright lighting for clear sight

-

correct air inlets and outlets for steady airflow

As a result, operators see better and finish faster.

B) Dust Collection and Ventilation

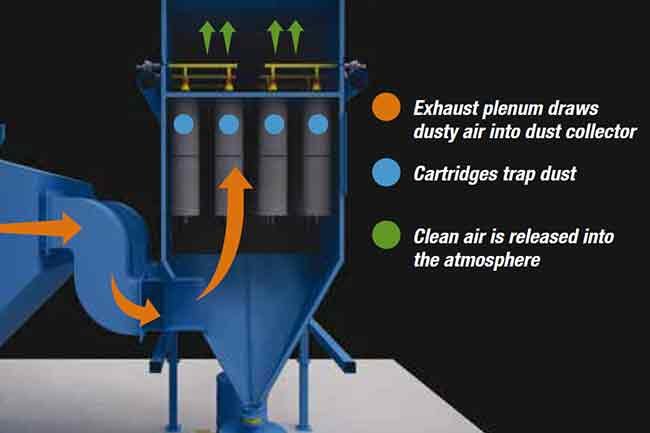

The dust collector pulls dusty air out of the room. In addition, the airflow keeps visibility high during blasting. After that, the system clears the room faster when the job ends. So, the room stays cleaner and safer.

C) Abrasive Recovery System

The recovery system collects spent abrasive from the floor and moves it to a central point. Then, it sends the abrasive to cleaning. As a result, you reduce sweeping time and cut media loss.

D) Abrasive Recycling and Cleaning Unit

The cleaning unit removes dust, fines, and debris from used abrasive. Next, it returns reusable abrasive to storage. Therefore, you keep stable blasting performance and lower your cost per job.

E) Blasting Pots, Hoses, and Nozzles

These parts control flow and pressure. Also, you can run multiple outlets for multiple operators. So, you increase output without frequent stops.

Elevate Your Business with Blasting Room Brilliance

Is downtime costing you money? Are traditional methods falling short on quality? Do you desire a solution that’s both swift and sophisticated?

Supercharge your business growth with the Blasting Room advantage. Discover the secret weapon that industry leaders use to stay ahead. Don’t just keep up; lead the way!

Call us today at +86 135 8931 7685

3. Applications of Blasting Room

Blast rooms support many industrial jobs. For example:

Surface Preparation

You can clean steel plates, frames, and fabricated parts before coating or painting. As a result, coatings bond better and last longer.

Decorative Blasting

You can blast stainless steel, aluminum, copper, and brass for a clean finish. In addition, you can control the look more easily.

Shot Peening

You can strengthen high-stress parts, such as torsion bars and structural parts. Therefore, parts last longer under repeated load.

Deburring

You can remove burrs and sharp edges from cut and stamped parts. So, you improve safety, fit-up, and product quality.

In short, if your parts are too large for a cabinet, a blast room often fits best.

Uncover Hidden Potential in the Blasting Room

4. Why install a blast room?

Run in Any Weather

Outdoor blasting stops when wind or rain rises. However, a blast room keeps work inside. So, you can run a stable schedule.

Get Consistent Results

A controlled room supports stable airflow and lighting. Therefore, you get uniform cleaning and a steady surface profile.

Cut Media and Disposal Cost

When you reuse recyclable media, you buy less abrasive and throw away less waste. As a result, operating cost drops over time.

Keep the Worksite Cleaner and Safer

Containment keeps dust and debris inside the room. In addition, good airflow supports better air quality near the operator. So, the site stays cleaner.

Struggling to Innovate? Break Free with Blasting Room!

Are you facing creative roadblocks? Do productivity issues hinder your success? Is your business growth plateauing? Unleash the Blasting Room, the remedy to your challenges!

Call us today at +86 135 8931 7685

5. Recovery system

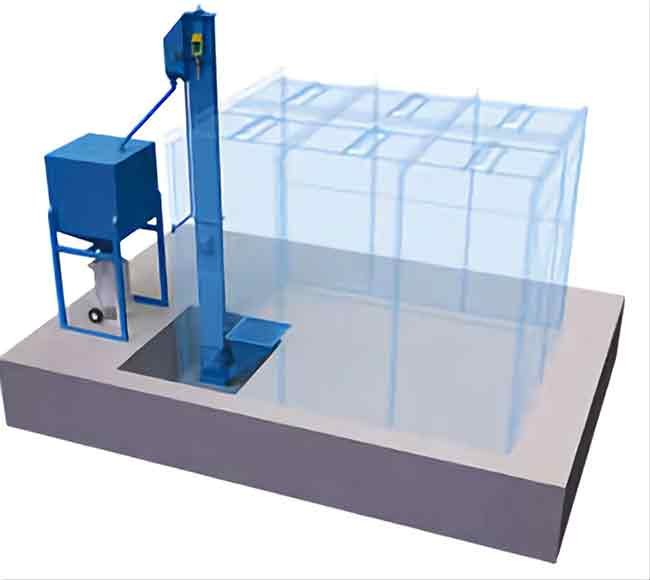

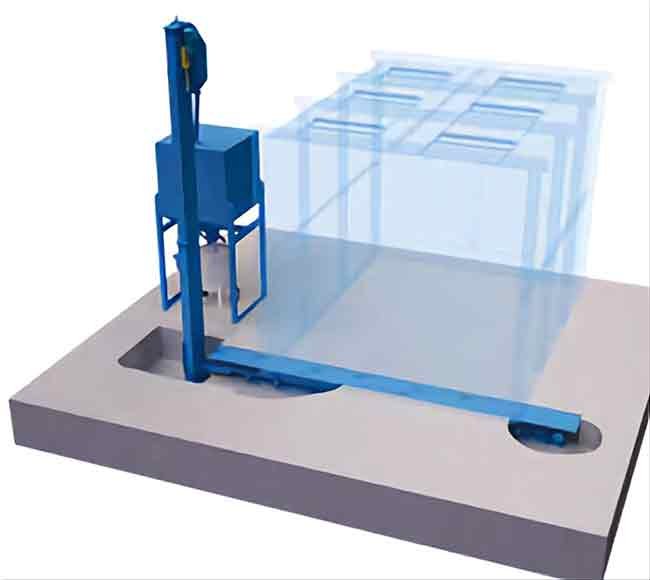

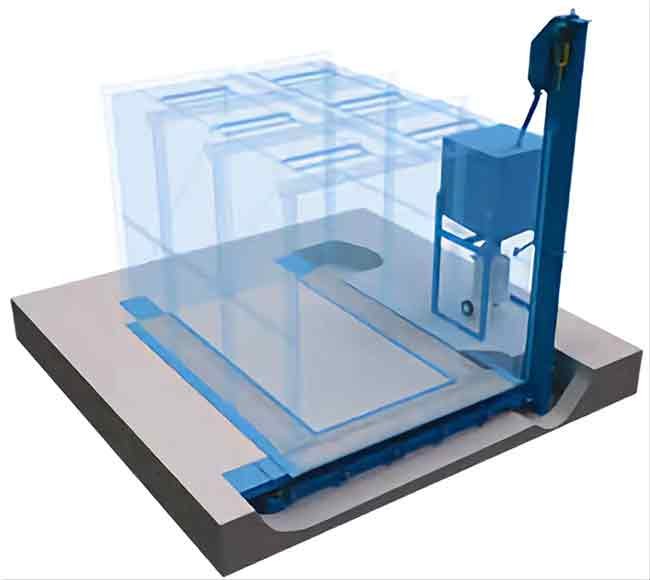

Recovery systems range from simple sweep-in hoppers to full under-floor recovery. So, you should choose based on output and labor.

100% Floor Recovery

A full recovery floor collects abrasive across the room. Therefore, operators spend less time handling spent media.

25% or 50% Floor Recovery

Partial recovery lowers initial cost. However, operators must sweep abrasive into the recovery zone each day. As a result, labor time increases.

Conveyor Types (Common Choices)

Next, conveyors move abrasive to a collection point:

-

Pneumatic recovery moves abrasive with airflow

-

Scraper conveyors handle heavy media well

-

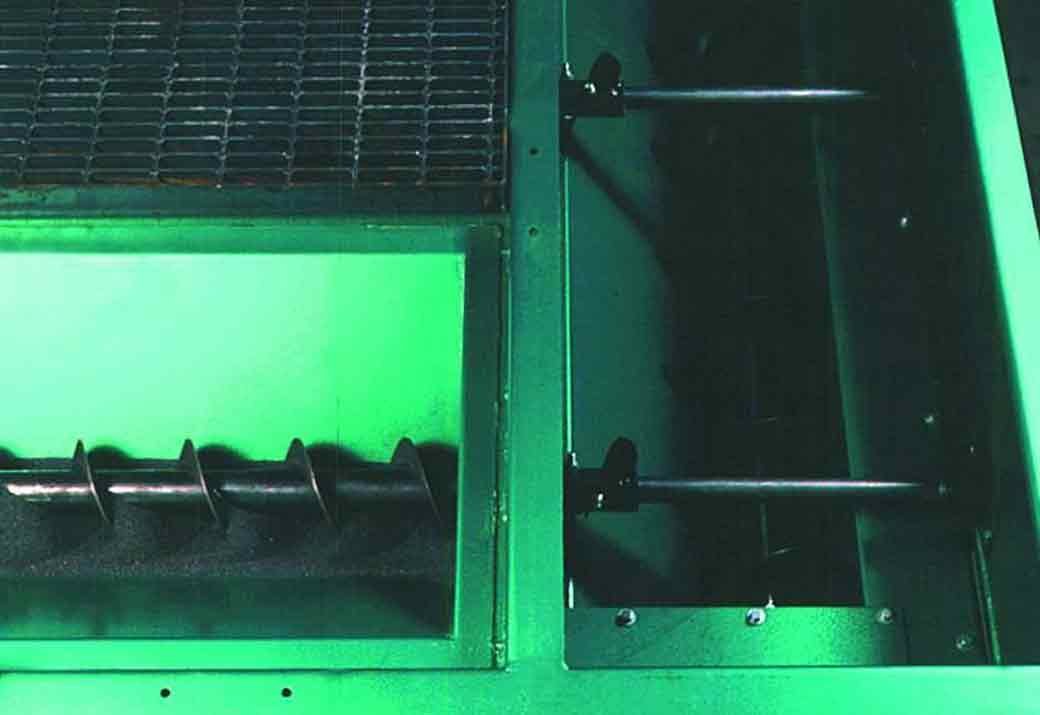

Screw conveyors support steady conveying

-

Oscillating trays run low and often need less service

Then, a bucket elevator lifts abrasive to the cleaning unit. Finally, the recycler returns usable abrasive to blasting.

Screw Conveyor Recovery Floor

Scraper Conveyor Recovery Floor

Pneumatic M Section Recovery Floor

Sweep Chute Abrasive Recovery System

I Type Abrasive Recovery System

U Type Abrasive Recovery System

Break Free from Constraints with Blasting Room

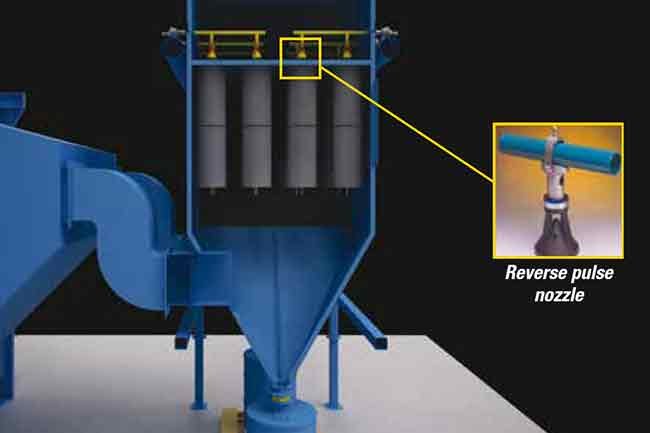

6. Blasting Room Dust Collectors

The dust collector controls visibility and cleanliness. So, we size it based on room volume, dust load, and blasting rate. If you size it wrong, dust builds up and visibility drops.

BlastKing HT type dust collectors help you:

-

collect dust efficiently

-

reduce dust emission

-

upgrade older systems that use small or weak collectors

As a result, you get cleaner air and steadier blasting.

Take the Leap into Infinite Innovation

Don’t let innovation pass you by. Seize the opportunity to transform your creative process with the Blasting Room. Join us on this journey towards infinite possibilities.

Call us today at +86 135 8931 7685

7. FAQs (Frequently Asked Questions)

8. Conclusion

In conclusion, the importance of blasting rooms in industrial processes is paramount. These controlled environments play a crucial role in enhancing the efficiency, safety, and precision of abrasive processes across diverse sectors. As technology advances, the capabilities of blasting rooms are expected to evolve, ensuring their continued indispensability in the industrial landscape.

It’s noteworthy that alongside traditional blasting rooms, more efficient solutions like dust free vacuum blasting machines and auto shot blasting machines for surface preparation have emerged. These machines offer enhanced efficiency and significant cost savings in terms of labor. They represent a technological advancement that complements or, in some cases, surpasses the capabilities of conventional blasting rooms. The continuous innovation in surface preparation technologies underscores the dynamic nature of the industrial sector, where optimizing processes is a constant pursuit for increased productivity and resource efficiency.