Technical Specifications

| Type | KST250E | KST250 |

|---|---|---|

| Engine | Motor | HONDA 390 |

| Power | 7.5Kw | 13HP |

| Working width (mm) | 250mm | 250mm |

| Working depth (mm) | 250mm | 5-8mm |

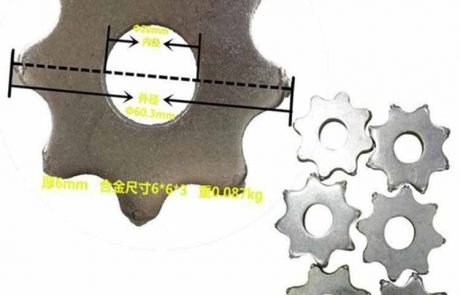

| shaft number for cutter | 6 | 6 |

| Cutter number (mm) | 108 | 108 |

| Operation Weight(kg) | 140 | 140 |

| Effeciency(m2/hr) | 40-70 | 40-70 |

| Overall Size(mm) | 910×470×880 | 910×470×880 |

| Packing Size(mm) | 1000×600×1050 | 1000×600×1050 |

Features for Concrete Floor Scarifier

· Long-life milling drums (tools) with 6 cutter shafts, with a variety of tool supply options for handling a wide range of materials;

· With depth indicating dial, precision pitch adjustment, precise control of milling depth; lifting handle can be light and flexible lifting and lowering drum frame;

· Vacuuming device and external water source with a suction port and a water inlet for quick connection;

·The engine adopts a four-stage cyclone air filter, which ensures that the machine can work continuously in a harsh environment, and greatly reduces the engine failure rate;

· Patented casting ball bearing assembly and waterproof and dustproof seals to reduce maintenance work;

·The patented tool holder quick disassembly design can complete the installation or disassembly of the tool within 5 minutes;

·Equipped with an engine safety flameout switch to quickly shut down the engine in an emergency.

Applications

· Base surface cleaning and leveling construction of bridge waterproof layer of high-speed railway

· Lightly brushed concrete, asphalt roads, epoxy, and wear-resistant floors

· Remove floor coatings, paint, various road markings

· Remove the old floor surface when the ground is damaged and the dirt needs to be refurbished