Introduction to The Shot Blasters for Fabrication and Construction

Ever wondered how giant steel beams can hold up a skyscraper without breaking a sweat? The secret lies in meticulous surface preparation in the steel industry. Among the top methods, shot blasting stands out for its ability to quickly remove rust, paint, and mill scale. For example, roller conveyor shot blasting machines efficiently clean metal surfaces by propelling high-speed abrasive media. As a result, the steel emerges tougher, smoother, and ready for any project—from supporting a tall building to giving your construction job a sleek, durable finish.

What Is Shot Blasting

Shot blasting involves projecting steel shots or grits at high speed onto metal surfaces. Consequently, this process removes contaminants, scales, and other unwanted materials, creating a clean and textured finish. Compared to methods like chemical cleaning or acid pickling, it is faster, more eco-friendly, and delivers consistent results. For these reasons, shot blasting remains the preferred technique in steel fabrication and construction.

Elevate Your Fabrication Game with Our Cutting-Edge Shot Blaster!

Key Benefits and Features

-

Customizable Blast Wheel Setup

Selecting the right tool for the job is crucial, and our blast wheel setup adjusts to match your workpiece’s shape and size effortlessly. -

Multiple Wheels, Multiple Possibilities

Whether your production requires high firepower or a lighter touch, the ability to add or remove wheels provides unmatched versatility. -

Smart Workpiece Recognition

By recognizing when a part is in place, the machine prevents wasted effort, ensuring every blast counts. In addition, this efficiency keeps your operations running smoothly.

-

High-Performance ORICA Double Disc Wheels

These wheels are engineered for exceptional cleaning power, leaving no spot untouched. -

Automatic PLC Control

Relax and let the system handle complex settings automatically. As a result, blasting operations are more straightforward than ever. -

Universal Machine for Sheet Metal, Profiles, and Welded Constructions

From flat plates to intricate assemblies, this machine accommodates a wide variety of projects with ease.

Tired of Rust and Scale Slowing You Down? We’ve Got the Solution!

Applications In Steel Fabrication and Construction

- Angled Blast Wheels

- Unlike Type G and Type HD machines, Type X machines have angled wheels. This design reaches awkward nooks and crannies on complex parts effortlessly.

- Bye-Bye, Tricky Surfaces

Welded constructions, flame-cut pieces, and prefabricated parts are no longer a challenge. No missed spots or leftover rust here. - Small but Mighty

Smaller parts? No problem. The four-wheel system efficiently removes grime, delivering spotless results. - Bigger is Better

For bulk blasting, scale up to 16 wheels for serious throughput. It’s like upgrading to heavy-duty mode for unmatched cleaning power. - Perfect for Preblasted Materials

Fabrications Constructions Shot Blaster conveyors work seamlessly with preblasted steel. This keeps production smooth and efficient. - Universal Upgrade

Add an abrasive removal station for versatility. With this upgrade, you can blast sheet metal, profiles, and welded constructions with ease.

- Coating and Painting Prep

A grimy surface can ruin a paint job. Shot-blasted metal attracts primers and paints like a magnet, creating a durable and visually appealing finish that stands the test of time.

- Fabrication Workflow Efficiency

Automation significantly boosts efficiency. By relying on a roller conveyor, production speeds up while physical strain on workers decreases—a double win for productivity.

- Consistent Surface Quality

Forget uneven patches or missed spots. With carefully controlled blasting settings, your steel achieves a uniform finish, eliminating the need for time-consuming rework.

- Enhanced Durability

Proper blasting not only cleans the surface but also improves resistance to corrosion. Consequently, this ensures fewer maintenance headaches and better performance over time.

- A Better, Faster Future

Streamlining surface prep with roller conveyor shot blasting isn’t merely about saving time or money. Instead, it’s about consistently delivering high-quality results that meet or exceed expectations.

Maximize Efficiency with Our High-Performance Shot Blasting Technology!

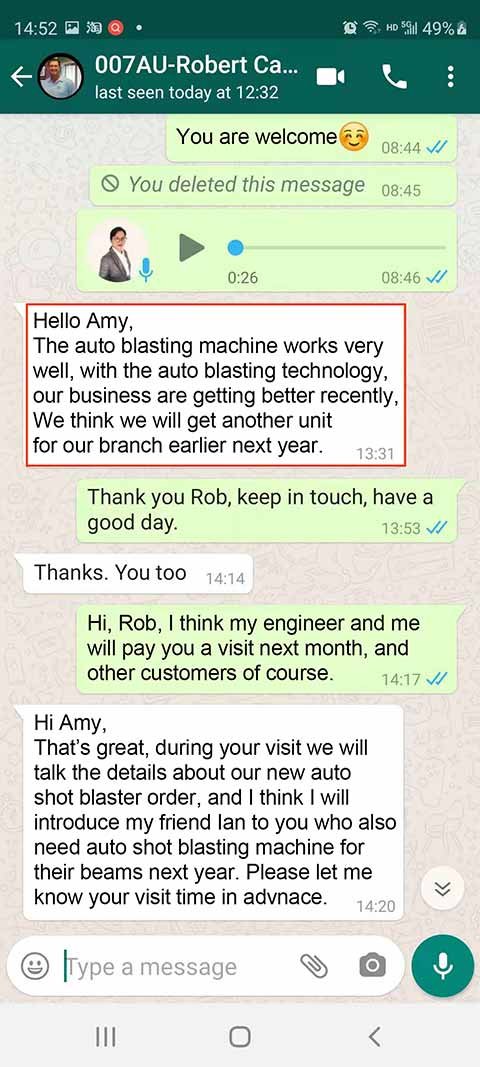

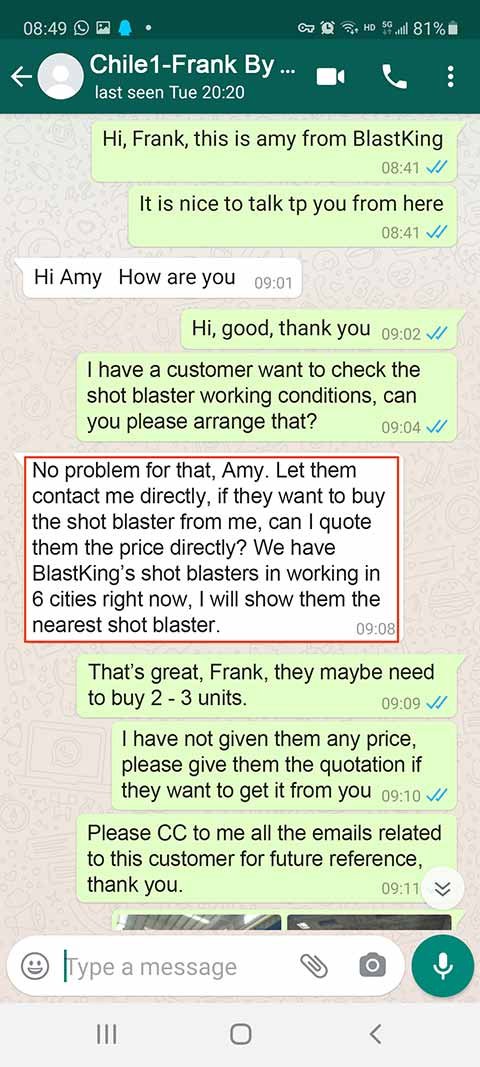

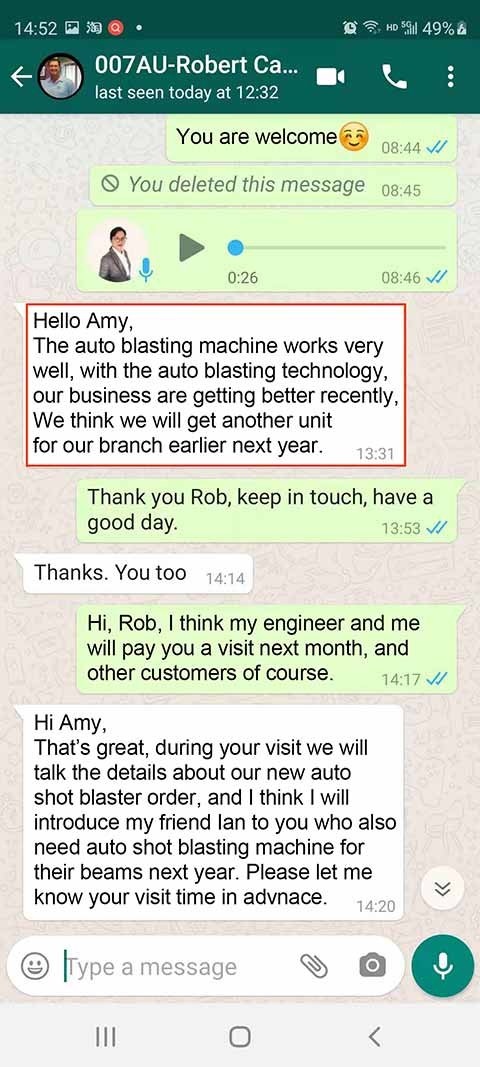

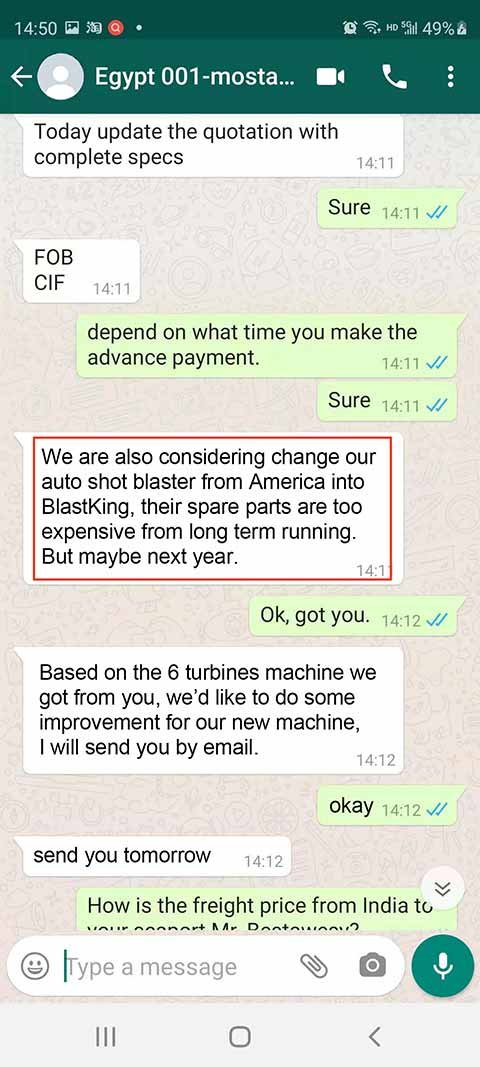

BlastKing Blasting Machine for Construction and Fabrication

- Angled Blast Wheels

Type X machines set their wheels at an angle (unlike the Type G and Type HD), helping reach those awkward nooks and crannies on complex parts. - Bye-Bye, Tricky Surfaces

Welded constructions, flame-cut pieces, and other prefabricated parts with base ends finally meet their match. No more missed spots or leftover rust. - Small but Mighty

Got smaller parts? A four-wheel system handles them just fine, zapping away grime without missing a beat. - Bigger is Better

If you’re blasting in bulk, ramp up to 16 wheels for serious throughput. Think of it as leveling up your cleaning power. - Perfect for Preblasted Materials

Fabrications Constructions Shot Blaster conveyors are designed for welded components made from preblasted steel, streamlining the process and keeping production moving. - Universal Upgrade

Add the optional abrasive removal station, and boom—you’ve got a universal blaster that can tackle sheet metal, profiles, and welded constructions. A real triple threat.

Protect Your Investment with Durable, Long-Lasting Equipment!

Concerned about the longevity and maintenance costs of your machinery?

Investing in equipment that wears out quickly is like pouring money down the drain. Our shot blaster features high-manganese liners and wear-resistant components, ensuring durability and reducing maintenance costs. Protect your investment and enjoy peace of mind.

Call us today at +86 135 8931 7685

Technical Specification

| Type | KB 7.5/2.5X | KB 7.5/5X | KB 15/5X | KB 15/10X | KB 20/15X | KB 25/15X | KB 30/15X | KB 30/20X |

|---|---|---|---|---|---|---|---|---|

| Machine entrance width (mm) | 850 | 850 | 1600 | 1600 | 2100 | 2600 | 3100 | 3100 |

| Machine entrance height (mm) | 300 | 550 | 550 | 1050 | 1550 | 1550 | 1600 | 2100 |

| Work speed (m/min) | 0.5-2 | 0.5-2 | 0.5-2 | 0.5-2 | 0.5-2 | 0.5-2 | 0.5-2 | 0.5-2 |

| Number of blast wheels | 4 | 4 | 4 | 4/6 | 6/8 | 6/8 | 8/10 | 14/16/18 |

| Power per blast wheel (kW) | 7.5 | 7.5/11 | 11/15 | 11/15 | 11/15 | 11/15 | 11/15 | 11/15/18.5 |

| Roller pitch (mm) | 800 | 800 | 800 | 800 | 800 | 800 | 800 | 800 |

| Alternative pitch (mm) | tailored by customer | tailored by customer | tailored by customer | tailored by customer | tailored by customer | tailored by customer | tailored by customer | tailored by customer |

Looking for an efficient way to streamline the blasting process for steel fabrication and construction? Tunnel-type shot blasting machines are a fantastic automated solution! They’re designed to handle large-scale projects with ease and precision. Want to dive deeper into how they work? Click here to learn more!

Seamless Integration into Your Production Line—No Hassle, No Fuss!

Blasting Cabinets and Abrasive clean unit

All-High-Manganese Steel Cabinet

Roller conveyor blast machines come lined entirely with high-manganese steel. This material toughens from 35HRC to beyond 60HRC—essentially creating armor that easily withstands intense abrasive hits.

Easy-Change Liners

Are you tired of dismantling half the machine to replace wear parts? These liners attach from the outside, making swaps quick and painless. It’s almost as satisfying as changing a car tire—if you’re into that.

Extra Armor When You Need It

For those using extra-aggressive shot, simply add another layer of high-manganese, tool steel, or cast linings. This provides an additional shield against wear and tear.

No More Rogue Shot

To prevent shot from escaping, multiple rubber layers or curtains are placed in heavy-wear spots. These are mounted on a V-track, making replacements straightforward. It’s like plugging leaks before they can turn into a mess.

Brush + Blow-Off Station Tag Team

After blasting, a rotating brush efficiently sweeps away leftover media. A high-pressure blow-off station then finishes the job, offering a spotless surface. It’s like a spa day for your workpieces, only with more steel and precision.

Interchangeable Brush Segments

The brush features segments that can be swapped out when worn. Instead of replacing the entire brush, you can simply refresh the parts that need it.

Built-In Recycling

The brush directs spent media into a specially designed trough. A screw conveyor then returns it to circulation. This feature saves on abrasive costs, making it both efficient and economical.

Adjustable Framework for Different Sizes

The brush and screw conveyor share a single adjustable structure. Whether handling mini profiles or large beams, alignment remains stress-free.

Final Media Blow-Off

On the same adjustable framework, a high-pressure ventilator completes the process by removing any residual granules. This final touch ensures that no media clings to your workpieces.

Reduce Labor Costs with Our Fully Automated Shot Blasting Solution!

ORICA Blast Turbine

Ever wondered how we pack so much punch into our machines? Meet our patented direct-drive blasting turbine. Offering motor power from 4kW to 75kW, it can handle anything from light-duty cleanup to intensive blasting marathons. Trust us to deliver the muscle you need.

Versatile Solutions for All Your Fabrication Needs!

Limited by equipment that can’t handle diverse workpiece sizes and shapes?

Equipment that lacks adaptability can hinder your operations. Our shot blaster accommodates a wide range of sizes and shapes, providing flexible solutions tailored to various fabrication needs. Expand your capabilities with this versatile technology.

Call us today at +86 135 8931 7685

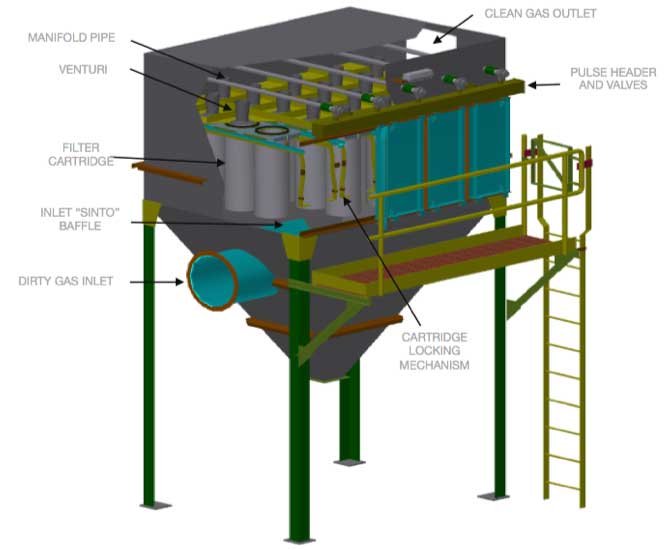

Cartridge Filter Unit

Generous Spacing Between Filter Folds

Picture extra elbow room—this spacing enables more precise cleaning while maintaining consistent air pressure.

Impact Separator

Acting as a bouncer, it removes broken fines before they can damage the filters. This prevents unnecessary wear and tear.

Easy Cartridge Swaps

With no complex steps or tools required, swapping cartridges is quick and straightforward. Just slide the old one out and the new one in.

Correct Contact Pressure

The filters stay secure and snug, ensuring steady performance without the guesswork.

Low Compressed Air Consumption

Consuming less air reduces costs and keeps your budget happy in the long term.

Top-to-Bottom Cleaning

The conical design ensures grime is cleaned evenly from start to finish. No spots are left untouched.

Experience Unmatched Support and Service with BlastKing!

We deliver results