Floor Shot Blasting Machine Introduction

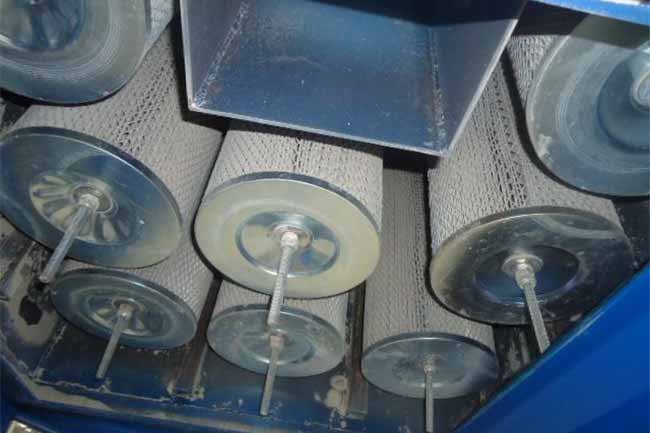

Floor shot blasting machines are robust equipment designed for efficiently cleaning, profiling, and preparing surfaces. They utilize abrasive materials propelled at high velocities to remove contaminants and create an ideal surface for coatings or overlays.

How Floor Shot Blasting Machine Works

BlastKing walk-behind shot blasting machines operate on a simple yet highly effective principle. These machines use abrasive materials propelled at high velocities to clean, strengthen, or polish surfaces. The abrasive material, often steel shots, is propelled onto the surface through a blasting wheel. This process not only removes contaminants but also profiles the surface, preparing it for coatings or overlays.

MODEL KBF200, KBF250, KBF550 AND KBF800

- Low cost, high production introductory self-propelled blast unit.

- 8” blast pattern. Prepares 50 to 450 sq. ft./hr.

- Self-propelled for even consistant surface profile

- Highly maneuverable, can be used for residential jobs

- Three phase power

- 10″ blast pattern, prepares 250 to 1,200 sq. ft/hr.

- KBF250 for light, medium or heavy removal.

- Redesigned separator, rebound plenum and blast housing increase shot cleaning efficiency, extending life of the wheel, liners and housing.

- Easy-access, slide-out screen pulls out from the separator for quick removal of debris.

- Cam style belt tensioning mechanism for the blast motor makes belt easier to tighten.

- 20″ blast pattern. Prepares 350 to 3,500 sq. ft./hr.

- Recommended for light to medium removal.

- Base elevates the machine for easier transport.

- The drive system with integrated brake is designed for ramps and inclines, allowing for consistent travel speed.

- Advanced separation system provides increased shot cleaning efficiency, promoting longer wear component life.

- A high-speed travel switch helps ensure uniform preparation by allowing for quick repositioning after each pass, without resetting the travel speed.

- 30″ blast pattern. The KBF800 prepares 1,200 to 9,000 sq. ft./hr.

- Recommended for light to medium removal. Excellent for warehouse floors or thin mil coating applications.

- Base elevates the machine for easier transport.

- The drive system with integrated brake is designed for ramps and inclines, making these units ideal for parking decks.

- A high-speed travel switch helps ensure uniform preparation by allowing for quick repositioning after each pass, without resetting the travel speed

- Low cost, high production introductory self-propelled blast unit.

- 8” blast pattern. Prepares 50 to 450 sq. ft./hr.

- Self-propelled for even consistant surface profile

- Highly maneuverable, can be used for residential jobs

- Three phase power

- 10″ blast pattern, prepares 250 to 1,200 sq. ft/hr.

- KBF250 for light, medium or heavy removal.

- Redesigned separator, rebound plenum and blast housing increase shot cleaning efficiency, extending life of the wheel, liners and housing.

- Easy-access, slide-out screen pulls out from the separator for quick removal of debris.

- Cam style belt tensioning mechanism for the blast motor makes belt easier to tighten.

- 20″ blast pattern. Prepares 350 to 3,500 sq. ft./hr.

- Recommended for light to medium removal.

- Base elevates the machine for easier transport.

- The drive system with integrated brake is designed for ramps and inclines, allowing for consistent travel speed.

- Advanced separation system provides increased shot cleaning efficiency, promoting longer wear component life.

- A high-speed travel switch helps ensure uniform preparation by allowing for quick repositioning after each pass, without resetting the travel speed.

- 30″ blast pattern. The KBF800 prepares 1,200 to 9,000 sq. ft./hr.

- Recommended for light to medium removal. Excellent for warehouse floors or thin mil coating applications.

- Base elevates the machine for easier transport.

- The drive system with integrated brake is designed for ramps and inclines, making these units ideal for parking decks.

- A high-speed travel switch helps ensure uniform preparation by allowing for quick repositioning after each pass, without resetting the travel speed

Transform Your Floors with Precision excellence!

Diverse Applications of Floor Shot Blasting Machine

Technical Specification

| Type | KBF200 | KBF270 | KBF550 | KBF800 | KBF1000 | KBF1200 |

|---|---|---|---|---|---|---|

| Blasting width (mm) | 200mm | 270 | 550 | 800 | 1000 | 1200 |

| Travel speed (mm) | up to 20m/min | up to 23m/min | up to 26m/min | up to 26m/min | up to 26m/min | up to 26m/min |

| Production capacity (m/min) | up to 50m2/h | up to 100m2/h | up to 450m2/h | up to 600m2h | up to 900m2h | up to 1100m2h |

| blast motor power(Kw) | 7.5 | 7.5 | 2×11 | 2×15 | 2×18.5 | 2×22 |

| Voltage | customized | customized | customized | customized | customized | customized |

| Dust hose connection(mm) | ⌀150×20000 | ⌀150×20000 | ⌀200×20000 | ⌀200×20000 | ⌀200×20000 | ⌀200×20000 |

| Dimensions | 1295 x 406 x 1193 | 1590 x 425x 1020 | 1956 x 711 x 1397 | 2286 x 1188x 1463 | 2200 x 1180x 1450 | 2450 x 1450x 1700 |

| Weight | 160kgs | 200kgs | 595kgs | 770kgs | 1100kgs | 1300kgs |

The technical data is not binding and may be subject to change.

Depending on the type of parts, production method, etc., further machine types and measurement specification sheets upon request.

Craft Impeccable Concrete Surfaces That Last!

Benefits and Features of Floor Shot Blasting Machine

- Easily maneuverable, self-propelled machine—forward and reverse.

- AC inverted drive motor with integrated brake for even, down-slope operation on ramps and inclines.

- Quick-lift rear caster assembly for easier transporting.

- Highly versatile and appropriate for medium- to large-job sites.

- Excellent for industrial floor prep, road and airport maintenance, ship decks, decontamination, and more.

- Labor and time-saving shot blasting process strips, cleans, and profiles in one step−cost-effective and friendly to the environment.

- It operates virtually dust-free when connected to the BastKing DC1220 & DC1230 dust collectors, which is healthier for the operator and coworkers.

Protect Your Concrete Investments, Avoid Costly Repairs!

💰 Concerned about frequent repairs eating into your budget for concrete structures? Our shot blasting solutions safeguard your investments, reducing maintenance costs significantly.

Call us today at +86 135 8931 7685

Vacuum-assisted Cartridge Dust Collector

The BlastKing Group’ DC-1230 and DC-1330 are for heavy duty dust collection systems that are designed for its compact power and maneuverability. It combines power, efficiency, safety, and productivity all into one durable machine. The DC-1230 and DC-1330 are compact dust collectors for the professional. The DC-1230 and DC1330 dust collector combines heavy duty power and performance with a compact and easy to use design, it is ideal for all types of applications, and all sizes of jobs.

- Medium size but compact dust collector for dust free working environment.

- Standard silencer for low sound level.

- Automatic air pulse jet cleaning system.

- Large dust bin option with easy hand click system and third wheel to remove the dust bin.

- Connection of 20m dust hose.

- One ergonomic lifting point on top of the machine for easy transport.

- All components are inside the body, so no risk of damage during work and transportation.

- On-board air pistol for cleaning purposes.

- Continuously working even while changing the dust bag capacity.

- Fan and compressor are able to be switched on and off separately, this enables more effective cleaning of the filters, without having to run the fan unit.

- Dimensions W / L / H: 757mm / 1031mm / 1243mm

- Weight: 90 kg

- Motor power: 2.2kW (The voltage and frequency can be customized)

- Dust extraction motor: 1 powerful motor

- Filter: 4 high quality cartridge filters

- Cleaning: Automatic pulse cleaning system

- Compressor motor power: 1.1kw

- Vacuum: 51 mbar

- Dust bag capacity: 80 litres

- Dimensions W / L / H: 757mm / 1731mm / 1643mm

- Weight :200 kg

- Motor power: 4Kw (The voltage and frequency can be customized)

- Dust extraction motor: 1 powerful motor

- Filter: 8 high quality cartridge filters

- Cleaning: Automatic pulse cleaning system

- Compressor motor

- power: 2.2kw

- Vacuum: 51 mbar

- Dust bag capacity: 150 litres

- Dimensions W / L / H: 762mm / 1720mm / 1651mm

- Weight :460 kg

- Motor power: 5.5/7.5Kw (The voltage and frequency can be customized)

- Dust extraction motor: 1 powerful motor

- Filter: 11 high quality cartridge filters

- Cleaning: Automatic pulse cleaning system

- Compressor motor

- power: 2.2/3kw

- Vacuum: 51 mbar

- Dust bag capacity: 200 litres

Enhance Safety and Aesthetics in Your Workspace!

FAQs (Frequently Asked Questions)

We deliver results