Technical Specifications

| Machine Type | HB7/12 | HB10/16 | HB12/18 | HB14/22 | HB16/23 | HB18/25 | HB30/30 |

|---|---|---|---|---|---|---|---|

| Max. diameter per cluster(mm) | 700 | 1000 | 1200 | 1400 | 1600 | 1800 | 3000 |

| max. height per cluster(mm) | 1200 | 1600 | 2000 | 2200 | 2300 | 2500 | 3000 |

| Max. weight per cluster(kg) | 600 | 800 | 1000 | 2000 | 3000 | 5000 | 10000 |

| No. of wheelsx Power(kw) | 2x 7.5 | 2x 7.5/11 | 2x11/15 | 3x 7.5/11/15 | 3x 7.5/11/15 | 4x 7.5/11/15 | 5x7.5/11/15 |

| Foundation pit | no | no | no | no | yes | yes | yes |

Features of Cylinder Shot Blaster

Versatile transport technology

Highly efficient blast wheels

Multiple machine sizes and variations available

Applications of Cylinder Shot Blaster

- Blast cleaning welded steel fabrications

- Deburring and homogenising diecast parts

- Peening dynamically stressed components

- Removal of mill and forge scale as well as rust

- Removal of burrs and scalesIncrease of surface roughness

- Shot peening to increase fatigue strength

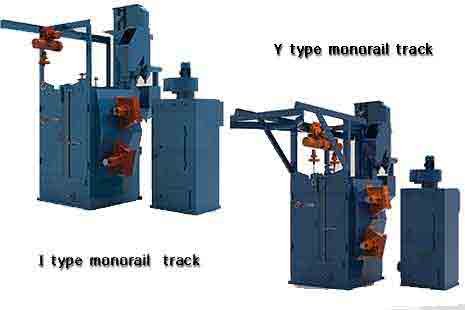

Cylinder Shot Blaster with Hanger System

BlastKing’s Cylinder Shot Blaster with Hanger System can be used for a wide spectrum of applications and workpiece shapes and sizes. Batches of small components or singular large, heavy workpieces can be treated.The workpieces are transported manually on rotating hooks or automatically on an overhead rail system into the blast cabinet. The blast cycle runs in accordance with the preset programme and blast time.

To achieve complete coverage, the workpiece carrying hooks rotate automatically in the blast cabinet. This rotation process means that even highly complex workpieces, with hard to reach surfaces, can be safely and accurately treated.

The transport system can be designed for different weights. As an option, carrying hooks are available with integrated hoists for operational ease and safety.

Shot Blasting Cabinet

As with all BlastKing roller conveyors Blast Machines the shot blasting cabinet liner is manufactured completely from high manganese. High manganese has a property which is hard enough to deal with the shot blasting from 35HRC to more than 60HRC. They are attached from the outside and are easy to replace. When aggressive shot is used, additional lining of high manganese, tool steel or cast material can be provided.

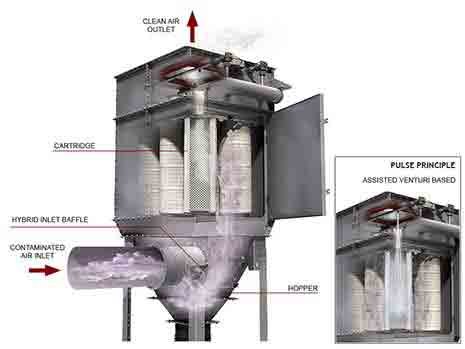

Cartridge Filter Unit

Each BlastKing machine is equipped with multiple cartridge filters. These filters are necessary to remove any impurities from the air used to blast resulting in a more even, direct, and effective blast.Benefits experienced with the BlastKing’ cartridge filters:

Large distance between folds in each cartridge filter leads to precise cleaning and better air pressure.

The impact separator within the cartridge filter unit ensures that the broken down fines are separated (which protects the filter cartridge against unnecessary wear).

The cartridge filters clean the cartridge automatically using an air pressure pulse, the intensity and duration of the pulse can be adjusted according to the type and amount of dust.

Pressure difference is monitored to automatically set the cleaning cycle increasing the life time of the cartridge and saves compressed air.

Easy exchange of cartridge filters.

Correct contact pressure.

Low compressed air consumption.

Constant cleaning, from top to bottom, due to conical design of the cartridge filter.

BlastKing ORICA Wheel

BlastKing group have the patented technology of the direct drive blasting turbine which motor power from 22kw to 75kw.

References to Cylinder Shot Blaster with Hanger System

Installation, Post-sales, Training & Safety

BlastKing Provide turnkey installation for the shot blaster. DIY installation by customer is also available according to the comprehensive documents, videos and drawings which provide by BlastKing, our engieers team also can provide real-time installation guidance.

The successful implementation of any blasting equipment is based upon the total commitment and dedication to the process. BlastKing’s field technicians are involved in the installation and training of the programmer and operator at the customer’s site or at BlastKing’s training facility. BlastKing has developed a complete program of maintenance training seminars. These are scheduled not only for new users but also for existing users. This structure is ideal for customers to send new employees so they can become more conversant with all BlastKing’s equipment.

Guarantee time of shot blasting machine will be one to five years. Technical support will be during the whole blasting machine life. Consumable spare parts will be supplied periodically.

All the equipment from BlastKing is conformity with CE&BV standard, and our factory have ISO9001, ISO14001 certification.

General emergency stop button is on all the BlastKing’s control panel. And sub emergency stop buttons are on conveyor systems. Detectors on the blast wheel covers, blasting chamber windows, elevators, separators will protect safety of the operators. Dust collection unit of shot blast machine dust emisssions is under 3mg/m3 which also bring dust free working environment.

FAQ

We will answer your email shortly!

Have questions or need help? We’re here to help you. Whether you are inquiring about a quote/order, seeking sales or site assistance, technical support or for general inquiries you’ve come to the right place. If you wish to contact BlastKing Group by email, please fill out the requested information below in order for us to better serve you.