Shot blasting is an incredibly versatile and highly effective surface preparation method. It is a preferred choice for various applications, and it’s not surprising that many opt for this approach. At BLASTKING, our complete dedication is to offer you comprehensive insights into the realm of shot blasting. Explore how this technique can genuinely transform your surface preparation requirements.

Manufacturer Since 1982

A Brief Overview of Shot Blasting

In the mechanical process of ‘shot blasting,’ abrasive particles are propelled with force onto a surface at high speeds. Specialized equipment propels these abrasive ‘shots,’ generating a significant impact on the targeted surface. As a result, this method effectively removes impurities, rust, scale, and old coatings. The outcome is a clean, flawless surface, immediately ready for use.

Types of blasting machine

Wheelblast machines come in various types primarily because they cater to diverse industrial applications and handle materials and components with varying properties. This categorization into different types allows for the development of specialized machines designed to effectively meet specific needs and address challenges in surface preparation and cleaning. Some common types include:

The Shot Blasting Process

Surface Preparation

Before starting the wheel blasting process, it’s crucial to make sure the surface is adequately prepared. To get the area ready for shot blasting, it’s essential to clear away any loose debris from the workspace. Proper surface preparation is a key factor in attaining the desired results.

Abrasive Selection

The key to a successful blasting process is choosing the right abrasive material. Typical options for abrasives encompass steel shots, steel grit, and various blasting media. The choice of abrasive hinges on the project’s particular requirements, including surface hardness and the types of contaminants to be eliminated.

Equipment and Machinery

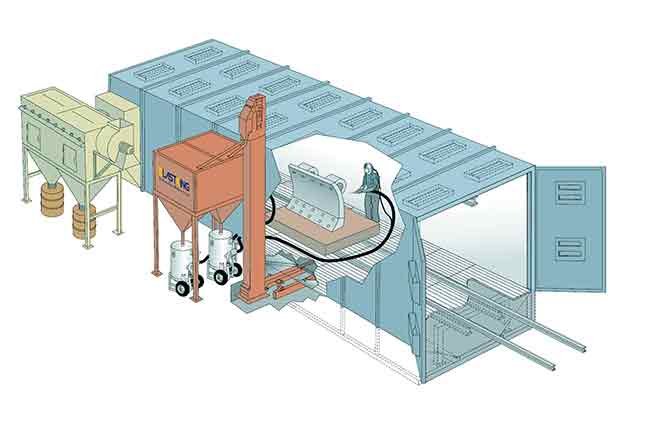

Shot blasters are specialized machines designed for shot blasting. They come in different shapes and sizes, making them suitable for both small and large projects. Shot blasters forcefully project high-speed abrasive materials onto surfaces, efficiently eliminating impurities and undesired coatings.

Surface Profiling

Auto blasting offers a distinct advantage by establishing a surface profile. This textured surface is crucial for improving adhesion in coating applications, guaranteeing secure bonding of paints and coatings to the substrate. Surface profiling is a critical step in the shot blasting process, especially in industries like construction and manufacturing.

We are manufacturer since 1982

Application of Shot Blasting

Auto blasting is widely employed across multiple sectors due to its versatility and effectiveness. Some noteworthy applications include:

Construction

In the construction field, automatic wheel blasting is employed to ready concrete surfaces for new installations. It efficiently eradicates contaminants, pollutants, and old coatings, leaving the surface clean, textured, and prepared for additional construction tasks.

Automotive

The automotive industry employs wheelblast to clean and prepare metal parts for painting or coating, ensuring a flawless and durable finish.

Aerospace

In the aerospace sector, wheelblast plays a vital role in the repair and cleaning of aircraft parts, aiding in corrosion and wear prevention and extending the life of critical components.

Manufacturing

Wheelblast is a process employed by manufacturers to prepare metal components for welding, painting, or powder coating, ultimately enhancing the strength and quality of the finished products.

Benefits of shot blasting

Efficiency

The highly efficient wheel blasting method rapidly removes surface impurities and outdated coatings. This efficiency results in shorter project timelines and decreased labor expenses.

Environmentally Friendly

Wheel blasting serves as an eco-friendly substitute for chemical cleaning methods as it doesn’t depend on harsh chemicals. Moreover, this approach decreases the need for hazardous waste disposal.

Surface Preservation

Automated blasting safeguards the integrity of the underlying surface by preventing damage or distortion. This is particularly critical for sensitive or valuable materials.

Versatility

Wheel blasting is a valuable choice for various applications due to its adaptability to different materials and surface conditions.

We are manufacturer since 1982

Upkeep and security

For wheel blasting equipment to perform at its best and last longer, regular maintenance is a must. Operators should also prioritize safety by wearing the right protective gear, ensuring adequate ventilation, and following equipment-specific safety guidelines.

Environmental Points to Take

While wheel blasting is considered environmentally friendly, it’s crucial to establish effective dust collection and waste disposal systems to minimize the environmental impact. Adhering to local regulations is vital for upholding ethical abrasive blasting practices.

Conclusion

Wheel blasting, known for its versatility and high effectiveness, finds widespread use across diverse industrial applications. It plays a pivotal role in achieving exceptional finishes by eliminating impurities, improving surface quality, and enhancing coating adhesion. Once the fundamentals and applications of wheel blasting are understood, informed decisions can be made regarding its utilization for specific projects.

The integration of wheel blasting into the surface preparation process offers several key benefits. These include environmental advantages, reduced maintenance expenses, and an overall enhancement in product quality. Whether operating in manufacturing, construction, or any other industry, grasping and implementing shot blasting can significantly impact efficiency and outcomes.

Furthermore, reaching out to industry experts for additional insights and customized auto blasting solutions tailored to specific needs is recommended. These professionals can provide valuable advice and support, aiding in the achievement of optimal results in surface preparation endeavors.

Lastly, it’s worth noting that various types of standard and non-standard customized blasting rooms are available, offering flexibility for different parts’ surface preparation methods. This adaptability ensures that businesses have options that suit their specific requirements and constraints.