Example of Brass forging shot blasting:

Taps and fittings

Pipe fittings

Sanitary appliances

Valves

Scope of shot blasting

Descaling

Deflashing

Which shot blasting machine ?

Brass forging Shot Blasting- batch type shot blasting machine

Components to be cleaned can be loaded by an open tote bin placed into the skip loader which hydraulically loads the work by tipping the tote bin to enable all pieces to discharge into the mill of the machine.

Maximum load of the machine is from 600 to 3000 kg depending on the model.

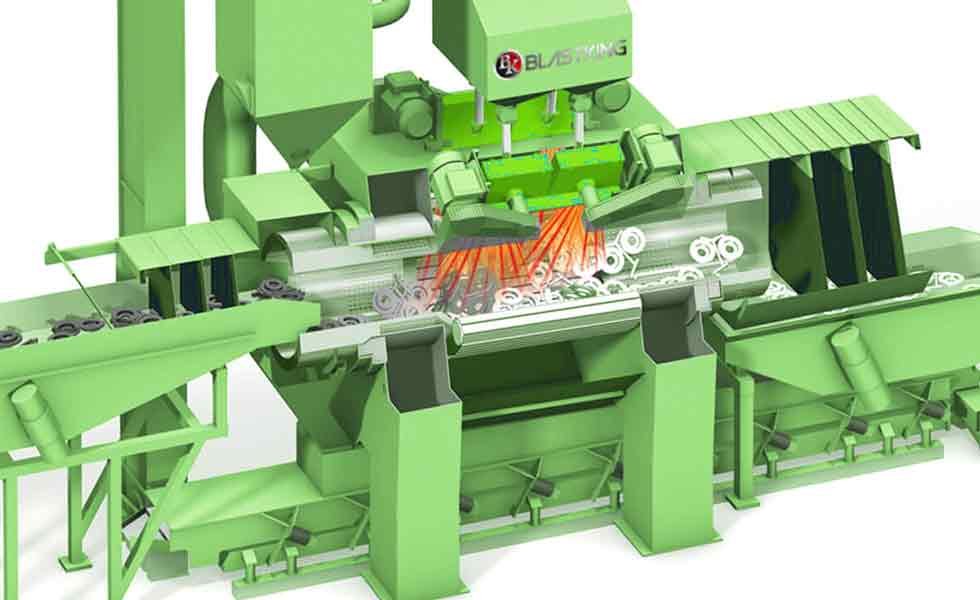

Continuous flow shot blasting machine type rocker barrel type

Continuous flow shot blasting machine for cleaning small to medium sized work-pieces.Work-pieces are conveyed in a regular and continuous flow presenting the surface to be treated to the abrasive.

The machine can be supplied with automatic loading/unloading systems.

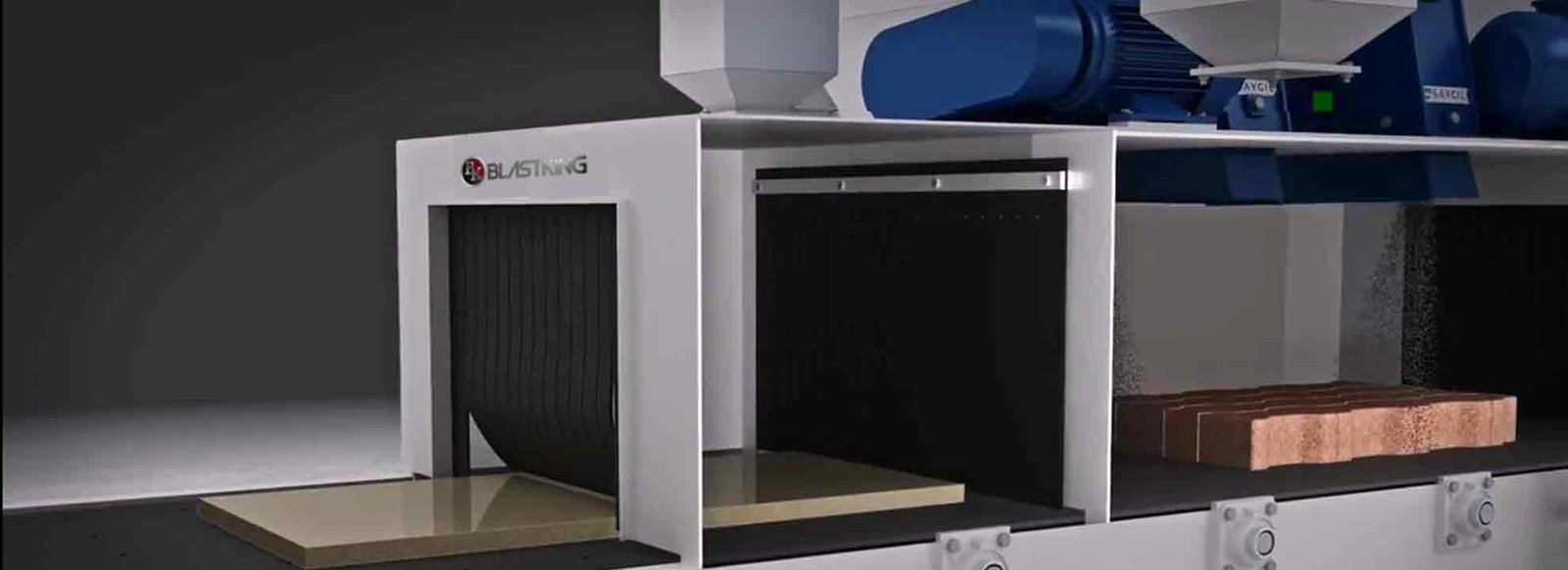

Brass forging Shot Blasting machine with wire mesh conveyor.

Work-pieces are placed on a high resistant wire mesh conveyor and blasted in only one passage through the blasting chamber.

Machine particularly suitable for high production and indicated to avoid deformation or damages of work-pieces (it is an alternative to Tumblast).

BlastKing Group’s Extensive Brass Forging Experiences

Related Products

Have questions or need help? We’re here to help you. Whether you are inquiring about a quote/order, seeking sales or site assistance, technical support or for general inquiries you’ve come to the right place. If you wish to contact BlastKing Group by email, please fill out the requested information below in order for us to better serve you.