1. What is a Blast Cabinet?

A blast cabinet is a specialized enclosed machine used for cleaning, smoothing, or etching surfaces with pressurized abrasive material. It’s widely utilized in industries such as automotive, aerospace, and metalworking for removing paint, rust, and other contaminants from metals, glass, and plastics.

Now, let’s talk about the different types of blast cabinets, because there are a few options depending on what you’re working with:

-

Suction Blast Cabinets – These work by pulling the abrasive media up with suction and applying it to the surface. It’s a solid choice for lighter tasks.

-

Pressure Blast Cabinets – Think of this as the heavy-duty version. It uses direct air pressure to shoot abrasive material onto the workpiece, getting the job done faster and more aggressively.

-

Wet Blast Cabinets – If dust is a concern, this one’s for you. It uses water mixed with the abrasive, which not only gives a smoother finish but also cuts down on the dust.

Each type has its strengths, so depending on your needs, there’s a perfect fit for the job. What’s great is how versatile these machines are—they can tackle all sorts of surface prep work!

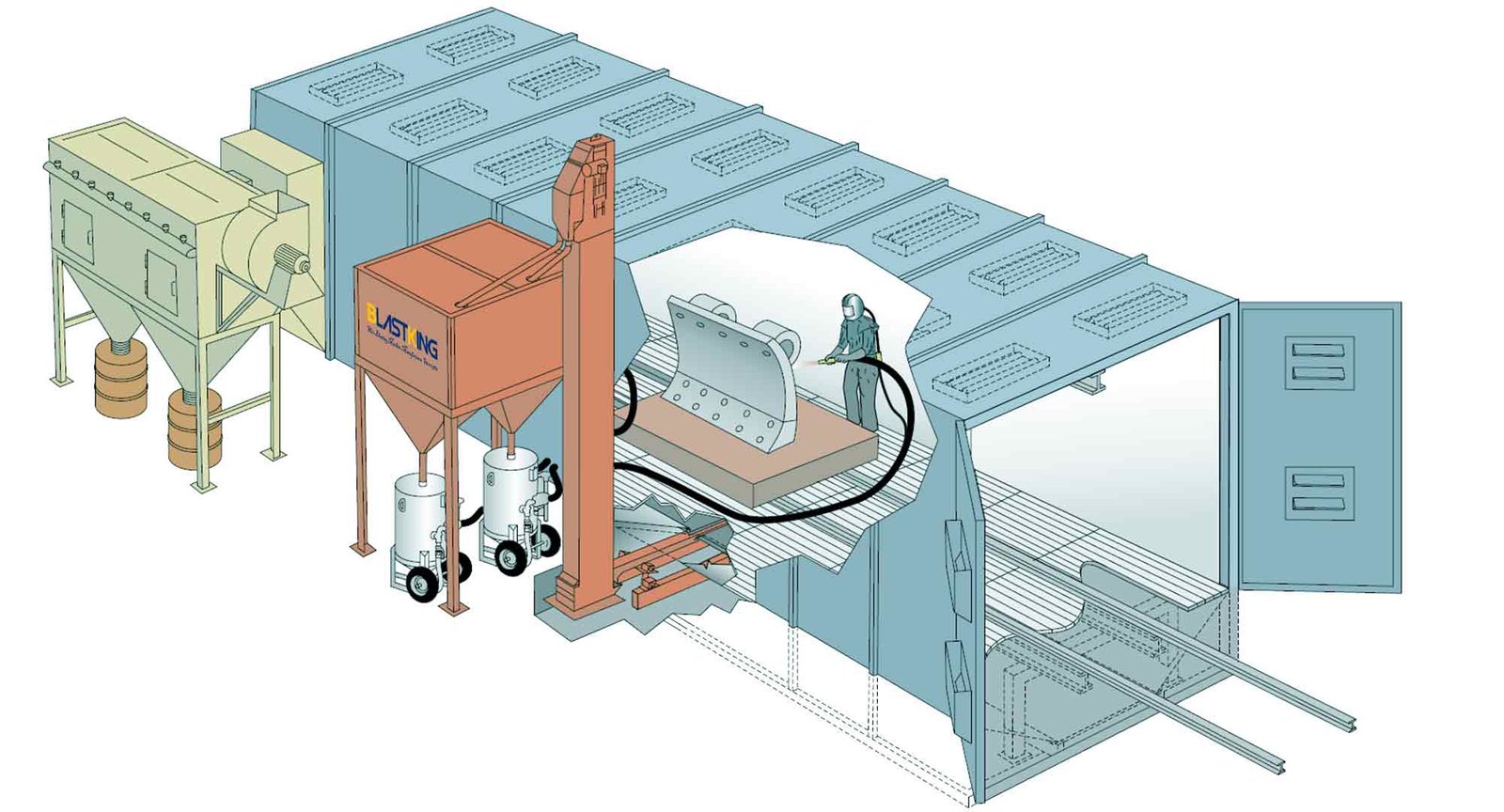

2. Revolutionize Surface Preparation with BlastKing’s blast cabinets!

Boost Efficiency and Cut Costs with Advanced Blasting Technology!

Investing in a blast cabinet with advanced blasting technology is a smart move for any business looking to increase productivity and improve results. With automated functions, efficient media recycling, and enhanced user comfort, modern blast cabinets offer numerous benefits that streamline operations and save money in the long run.

Whether you’re looking to enhance surface preparation, speed up cleaning processes, or simply improve your workflow, upgrading to a high-tech blast cabinet is a solid investment.

3. How Advanced Blasting Technology Enhances Productivity

Modern blasting technology has really stepped up its game, and if you’re still scrubbing surfaces by hand or using clunky, outdated machines, it’s like trying to cut down a tree with a butter knife. Let’s talk about how this new tech can make your life easier and your work faster.

A. Automation: Your New Best Friend

Think of automation like that extra set of hands you always wish you had. With automatic media reclamation, programmable nozzles, and preset cycles, you don’t have to babysit the process anymore. Just set it, forget it, and watch as your production speed kicks into high gear. Plus, every part gets the same treatment, no more worrying about uneven results. It’s like having a robot that does exactly what you want, every single time!

B. Recycling Abrasives: Waste Not, Want Not

Remember when you were a kid, and your parents told you to finish everything on your plate? Well, modern blast cabinets take that philosophy to heart by recycling abrasives. Instead of throwing away good material, these machines filter and reuse it. That means less waste, more savings, and—best of all—you spend less time stopping to refill the thing. It’s like the machine that keeps on giving.

C. No More Dust Clouds

Ever tried working in a room full of dust? It’s like trying to drive through fog with your headlights off. Advanced dust collection systems clear the air, literally. Better visibility means you can stay focused on the task, and you don’t have to stop for cleanup every five minutes. Not to mention, you’re breathing easier—your lungs will thank you later.

D. Designed with You in Mind

Let’s face it—working long hours on your feet can be a grind. But modern blast cabinets are built to make things more comfortable. Adjustable workspaces, easy-to-use controls—it’s like they were designed by someone who’s actually done the job before. Less strain on your body means you’re sharper, faster, and less likely to make mistakes.

Your Success, Our Priority!

4. Key Things to Think About

When you’re shopping for a new blast cabinet, remember:

- The Right Media: Make sure your cabinet is compatible with whatever you’re working with, whether it’s glass beads, plastic pellets, or something else.

- Size Matters: Bigger parts need bigger cabinets, so don’t squeeze yourself into a machine that’s too small.

- Automation: If you need precision and consistency, look for programmable features.

- Budget Smarts: Think about long-term savings. It might cost more upfront, but you’ll make that back in saved time and materials.

Investing in advanced blasting technology is like upgrading from a hammer to a nail gun—more speed, less effort, and better results every time.

Revolutionize Your Surface Preparation with Automated Sand Blasters!

Is downtime costing you money? Are traditional methods falling short on quality? Do you desire a solution that’s both swift and sophisticated?

Discover the seamless blend of efficiency and elegance with our airblast equipment. Elevate your space while minimizing downtime.

Call us today at +86 135 8931 7685