1. What is the differences between shot blasting and sand blasting?

When it comes to surface preparation, two common methods stand out: shot blasting and sand blasting. Shot blasting and sand blasting are both methods of surface preparation, but they diverge in their approach and impact. Shot blasting employs high-velocity steel shots to clean and prepare surfaces, while sand blasting utilizes sand particles propelled at high speeds for the same purpose.

While both techniques aim to achieve a clean and properly profiled surface, they differ in their processes, applications, and the types of abrasive materials used. Understanding these distinctions is crucial for selecting the appropriate method for a given project.

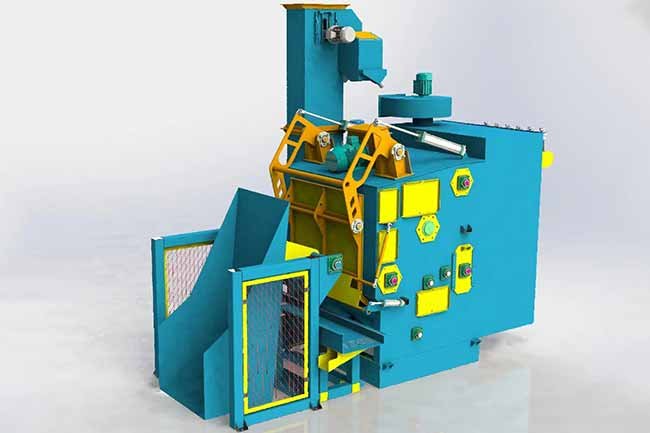

2. Shot Blasting: Precision in Propulsion

The Mechanism

Shot blasting, also known as abrasive blasting, involves propelling small metallic or abrasive particles at high velocity onto a surface. These particles, typically steel shots, are directed by the force of compressed air or centrifugal wheels. The impact of these shots effectively removes contaminants, coatings, and imperfections from the surface.

Applications

- Surface Cleaning and Profiling: Shot blasting is highly effective in cleaning and profiling surfaces, providing a consistent texture for coatings to adhere to.

- Deburring and Descaling: It’s ideal for removing burrs and scales from metal surfaces, leaving them smooth and ready for further processing.

- Rust and Corrosion Removal: The kinetic energy of the shots helps in eliminating rust and corrosion, extending the life of metal components.

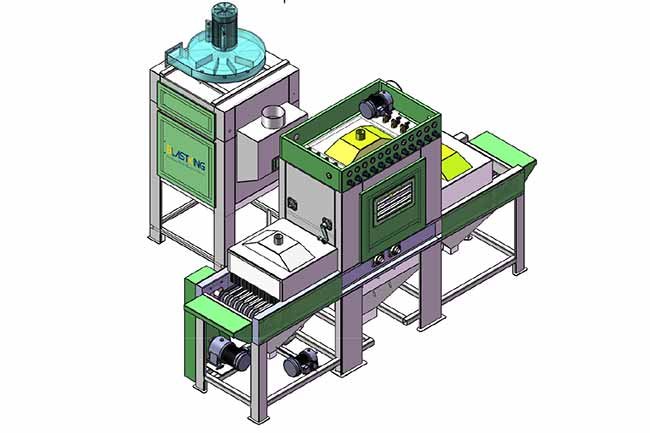

3. Sand Blasting: Abrading with Abrasives

The Mechanism

Sand blasting, on the other hand, employs sand or other abrasive materials propelled by compressed air or water at high speed onto a surface. The abrasives abrade the surface, effectively removing contaminants, paint, or rust. While sand was historically a popular abrasive, other materials like garnet, aluminum oxide, or glass beads are often used today.

Applications

- Paint Stripping and Coating Removal: Sand blasting is effective in stripping old paint and coatings from surfaces, preparing them for refinishing or repainting.

- Corrosion Removal: Similar to shot blasting, sand blasting can remove corrosion, making it suitable for treating metal surfaces.

- Etching and Surface Texturing: In certain applications, sand blasting is used for creating texture or patterns on surfaces for artistic or decorative purposes.

Are You Tired of Wasting Time and Money on Surface Treatment?

If you’ve ever felt the frustration of not knowing which blasting method to choose, you’re not alone. The wrong decision can lead to costly mistakes. Let us guide you to the right solution, saving you time and resources.

Call us today at +86 135 8931 7685

4. Key Differences: Shot Blasting vs. Sand Blasting

1. Abrasive Material:

- Shot Blasting: Involves metallic shots, usually steel, for impact.

- Sand Blasting: Utilizes abrasive materials like sand, garnet, or beads for abrasion.

2. Surface Finish:

- Shot Blasting: Leaves a smoother and more even surface finish.

- Sand Blasting: Can result in a more textured surface due to abrasive impact.

3. Purpose:

- Shot Blasting: Primarily used for cleaning, profiling, and preparing surfaces for coatings.

- Sand Blasting: Suitable for tasks like paint stripping, coating removal, and surface texturing.

4. Environmental Impact:

- Shot Blasting: Generally considered more environmentally friendly as metallic shots can be recycled.

- Sand Blasting: Environmental concerns arise due to the potential health hazards of silica in traditional sandblasting; alternative abrasives are often preferred.

Blasting into the Future: Which Technique Will Propel Your Project to Success?

5. Precision and Control

Shot Blasting:

- Precision: Offers precise control over the blasting process, making it suitable for targeted surface preparation.

- Ideal for: Projects requiring specific surface profiles and consistent results.

Sand Blasting:

- Precision: May have less precise control compared to shot blasting.

- Ideal for: General cleaning and smoothing tasks where extreme precision is not critical.

6. Cost Considerations

Shot Blasting:

- Initial Cost: Shot blasting machines may have a higher initial investment.

- Operational Costs: Lower operational costs due to the recyclability of steel shots.

Sand Blasting:

- Initial Cost: Sand blasting equipment is generally more affordable.

- Operational Costs: May incur higher operational costs due to the consumable nature of sand.

Transform Your Surface Treatment Experience

7. Speed and Efficiency: Shot Blasting vs. Sand Blasting

Shot Blasting:

- Speed: Generally faster than sand blasting, making it suitable for large-scale projects.

- Efficiency: High efficiency in removing contaminants and preparing surfaces.

Sand Blasting:

- Speed: May be slower than shot blasting, especially for larger surfaces.

- Efficiency: Effective but may require more time and abrasive material for comparable results.

8. Special Considerations

Shot Blasting:

- Hard Surfaces: Particularly effective on hard surfaces like concrete and metal.

- Coating Removal: Ideal for efficient removal of tough coatings.

Sand Blasting:

- Delicate Surfaces: Suitable for delicate surfaces such as wood or softer metals.

- Artistic Applications: Commonly used in artistic projects for detailed designs and textures.

9. Noise Level

Shot Blasting:

- Noise: Generally produces higher noise levels due to the impact of steel shots on the surface.

Sand Blasting:

- Noise: Can be quieter compared to shot blasting, making it more suitable for environments with noise restrictions.

10. Maintenance Requirements

Shot Blasting:

- Maintenance: Requires regular maintenance, including checking and replacing wear parts.

Sand Blasting:

- Maintenance: Generally has lower maintenance requirements, making it user-friendly.

Connect with Us Today!

Whether you have questions, need clarification, or are ready to embark on your surface transformation journey, our team is here for you. Connect with us today and let’s sculpt a future of surface treatment excellence together.

Call us today at +86 135 8931 7685

11. Project-Specific Considerations

Shot Blasting:

- Large Projects: Ideal for large-scale industrial projects where efficiency and precision are paramount.

- Structural Steel: Particularly effective for preparing structural steel surfaces.

Sand Blasting:

- Versatility: Well-suited for smaller projects or tasks that demand a versatile approach.

- Restoration Work: Commonly employed in restoration projects, especially for delicate or historical surfaces.

12. Health and Safety Considerations

Shot Blasting:

- Worker Safety: Requires proper training and adherence to safety protocols due to the impact force of steel shots.

- Respiratory Protection: Necessary precautions to protect workers from dust and airborne particles.

Sand Blasting:

- Dust Exposure: Adequate ventilation and respiratory protection are crucial to minimize exposure to airborne particles.

- Operator Training: Proper training is essential to ensure safe and effective sand blasting operations.

Claim Your Free Consultation

13. Conclusion: Choosing the Right Method

In conclusion, the choice between shot blasting and sand blasting depends on the specific requirements of the project. Shot blasting is favored for applications demanding a textured surface and precise control, especially in industrial settings. On the other hand, sand blasting is versatile and suitable for a range of tasks, from cleaning to artistic applications, where a smoother finish is acceptable.

Understanding the differences between shot blasting and sand blasting allows professionals to make informed decisions, ensuring optimal results in surface preparation for various projects.

14. FAQs (Frequently Asked Questions)

Ready to Take the Leap?