Shot blasting machine is a surface preparation equipment in which the steel grits/steel shots are accelerated and thrown on the surface of a material object at high speed by means of blasting turbines. In the 1930s, American companies made the world’s first shot blasting machine. The production of shot blasting equipment in China began in the 1950s and was largely based on Soviet technology.

Wheel blast machines can also be used to remove burrs, diaphragms, and rust that may affect the integrity, appearance, or definition of an object’s parts. The machine can also target a partially coated surface to remove surface contaminants and provide a surface profile that increases the coating’s adhesion to the surface for the purpose of shot blasting the workpiece. A shot peening machine differs from a wheel blasting machine in that it is used to reduce the fatigue life of a part by increasing different surface stresses, increasing the strength of a part, or preventing micromotion. Shot blasting machines are primarily used to treat the surface of steel products in large quantities during the steel production process. The use of shot blasting machine can effectively remove burrs on the surface of steel products, as well as some large-scale rust, in the use of shot blasting machine, if not master the technology, it is likely to cause the integrity of the surface of steel products, the light will cause surface abrasions, and serious will cause a serious poor appearance, affecting the product image.

For steel production, shot blasting machine is inevitable equipment, and the use of shot blasting machine for steel sand as well as steel shot surface treatment, is also an essential process, is the removal of steel sand, steel shot surface stains, rust, and a necessary procedure to check the integrity of the product surface, is essential.

The role of the shot blasting machine:

- Instead of the ordinary cold, hot forming process, the large thin-walled aluminum parts molding process, not only to avoid the parts surface residual tensile stress, but also to obtain the parts of the compressive stress is beneficial.

- Make the surface of the part to produce compressive stress and can improve the fatigue of the part and the ability to resist tensile stress corrosion.

- Correct the distorted thin-walled parts.

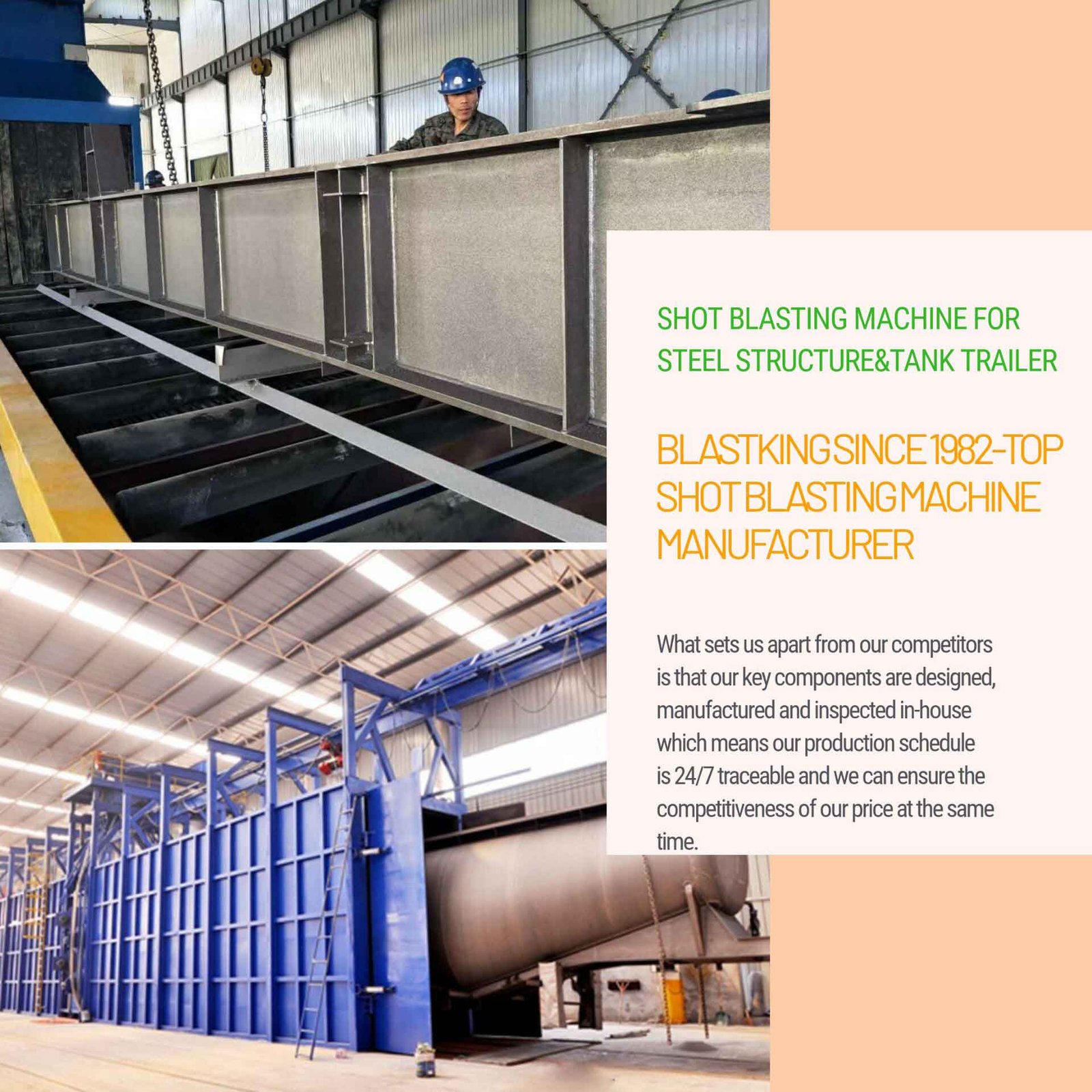

Blasting turbines are components of shot blast machine will projectile abrasive at high speed, so as to achieve the purpose of cleaning or strengthening of the surface, generally speaking, this equipment can do at the same time in addition to the core, cleaning and sand treatment, in many places will be called sandblasting machine or sandblasting machine, the following by the blasting machine manufacturer of BlastKing to explain the main functions and applications of the shot blasting machine what are.

The main function

Can remove the cast steel, cast iron surface of the oxide skin or sticky sand, the surface of the casting to play a role in cleaning, but also the quality of the castings for inspection of a necessary step, the large turbine casing to go in front of the line after shot blasting to detect injuries, so as to ensure reliable results. Hook type blast machine is divided into single hook and double hook, hook type blast machine by two hook loading workpieces alternately into the blast cleaning room. The shot blast machine is used to throw 0.2 to 0.8 pellets to the surface of the workpiece, making the surface of the workpiece to a certain roughness, making the workpiece beautiful, or changing the compressive stress of the workpiece to improve the life of the workpiece. For the castings, shot blasting is the necessary process to discover the existence of the surface of the skin, the skin of the pores, and other defects, through the shot blasting can ensure that the casting has a high quality.

In the modern theory of the strength of metals, as long as the density of the internal dislocation of the metal can be increased, the strength of the metal can be increased, and the use of a blasting machine blast to enhance the dislocation of the structure, which can help to improve the strength of the metal, this way is very effective for those who can not use the phase change of the hardened metal.

Through the shot-blasting can form compressive stress on the surface of the casting, which can make the castings of tensile strength, corrosion resistance, and fatigue strength have been enhanced, but also to correct those distorted thin-walled castings, can replace the ordinary hot and cold forming process, on large thin-walled castings to process, to avoid those residual tensile stress to obtain useful compressive stress.

The application field

- can be applied to the manufacture of bearings, generally speaking bearing surface requirements smooth, available shot blasting to remove burrs and impurities. Shot blasting machine is different from the shot blasting machine, is that this is used to reduce the fatigue life of the parts to increase the different surface stresses, increase the strength of the parts, or to prevent micro movement. According to modern metal strength theory, increasing the dislocation density within the metal is the main direction to improve metal’s strength. It has been proved that shot blasting is a proven method to increase the dislocation structure of the metal.

- can be applied to shipbuilding, shipbuilding steel plate has most of the rust, the use of shot blasting can be a very good way to remove rust operation.

- can be applied to the manufacture of automobiles, many of the steel plates and castings used in automobiles require polishing, but need to be able to maintain the original shape and strength of the plate, the use of shot blasting will be able to be polished without physical damage. Machine parts can be used to remove burrs, diaphragms, and rust that may affect the integrity, appearance, or definition of an object part. The blast machine can also be targeted at a partially coated surface to remove surface contaminants and provide a surface profile that increases the adhesion of the coating for the purpose of strengthening the workpiece.

- Can be applied to the manufacture of hardware products, with the blasting process that can meet the hardware flat, smooth and clean requirements.

- can be applied to the field of electroplating, electroplating requirements and hardware requirements are similar, of course, can also be used to deal with.

- can be used in the field of motorcycle parts manufacturing, will usually use the roller type equipment to complete the shot blasting operation.

- In addition to the above, the shot blasting machine can also be used in the field of steel plate manufacturing, used to deal with new steel burrs and other issues, can also be used in the field of valve manufacturing, for the valve castings to polish and polish, so as to achieve product quality requirements.

Have questions or need help? We’re here to help you. Whether you are inquiring about a quote/order, seeking sales or site assistance, technical support or for general inquiries you’ve come to the right place. If you wish to contact BlastKing Group by email, please fill out the requested information below in order for us to better serve you.