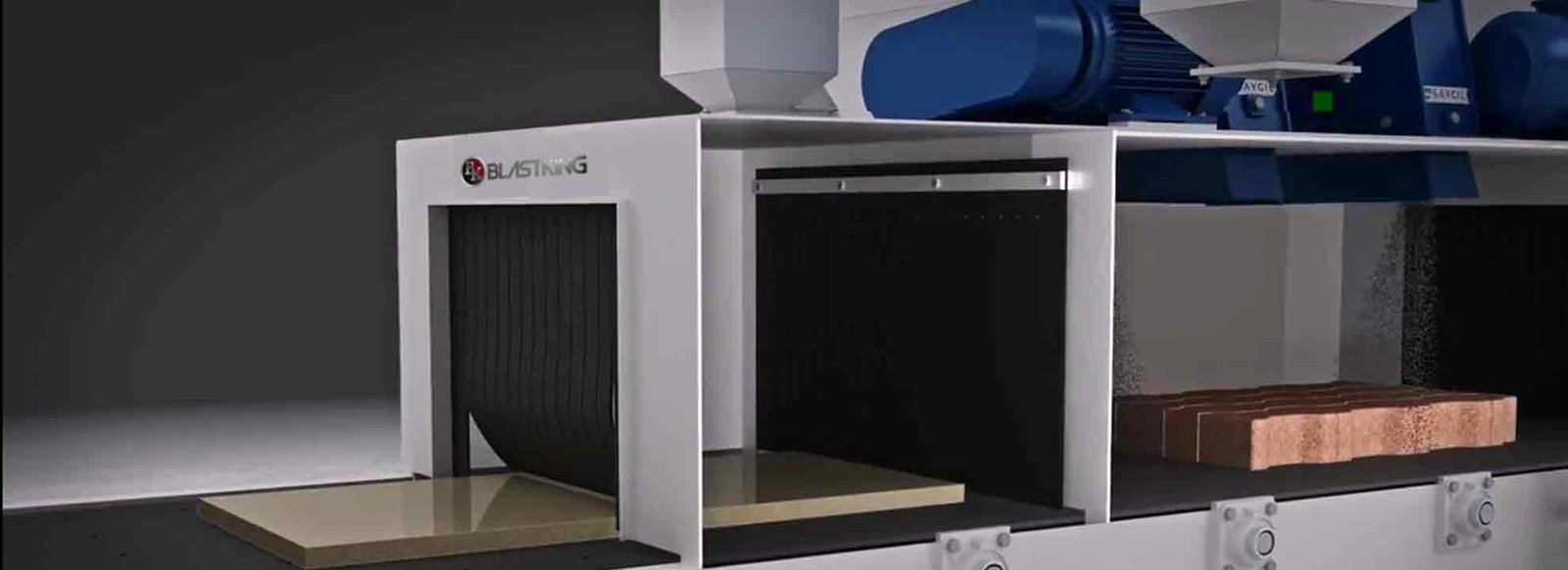

BlastKing’s Wire Mesh Shot Blasting Machine is very flexible in its application. The fact that workpieces can be blasted simultaneously from above and below considerably increases the spectrum of workpieces that can be treated. Wire mesh conveyor shot blast machines are used for, among other things, de-burring, de-scaling and cleaning of castings and laser-cut parts. The working principle: different sized abrasive, thrown by the rapidly rotating blast wheel, is accelerated towards the surface being prepared. The huge impact force of the abrasive quickly etches a unique three-dimensional character of the surface.

The Wire Mesh Shot Blasting Machine is excellent for all-round, complete and continuous blasting treatment of flat as well as voluminous and very complex components.

With 4 or 8 high power turbines, mounted around the housing (both vertically and horizontally inclined), The Wire Mesh Shot Blasting Machine is also possible to treat very complex components, which have “pockets” or difficult to reach areas. A highly wear-resistant wire mesh belt, with tension adjustment, provides the part transport.

Workpiece conveyor system to the enclosed shot blasting chamber, the use of the high-speed rotation of the impeller of the blast wheel after throwing playing steel cut wire or cast steel shot (projectile) accelerated to the workpiece surface, the impact on the workpiece surface, scraping to clear the workpiece surface rust and dirt. The workpiece move by the auxiliary chamber workpiece serves Submit roller on.

The products processed in this way have a high-quality surface appearance without overlapped and dead zone, it also has high production efficiency and low cost. Comparison with the old sandblasting process method, it has higher efficiency and lower cost, and if connected to our dust collector, the dust and contaminants will be recycled automatically at a very low dust emission level, which complies with EU environmental standards. It has a strong market competition and prospective application in stone industry.

Depending on customer’s needs it is possible to adjust the feeding speed and the throwing speed of the shots, e.g. at a surface corrosion level or to reach the requested roughness.

We have a complete series of wire mesh shot blasting machine with a transport width of 600-800-1000-1200-1500-2000 mm as a reference in China and other countries.

Have questions or need help? We’re here to help you. Whether you are inquiring about a quote/order, seeking sales or site assistance, technical support or for general inquiries you’ve come to the right place. If you wish to contact BlastKing Group by email, please fill out the requested information below in order for us to better serve you.