Skew Roll Shot Blasting Machine Basic Specification

| Type | SR 8-20 | SR24-60 |

|---|---|---|

| Maxi. Pipes diameter (mm) | 200 | 600 |

| Work speed (m/min) | 0.5-18 | 0.5-18 |

| Number of blast wheels | 2/4/6 | 2/4/6 |

| Power per blast wheel (kW) | 7.5/11 | 7.5/11/15/18.5 |

| Roller pitch (mm) | 600 | 600 |

| Alternative pitch (mm) | tailored by customer | tailored by customer |

Application for Skrew Roll Shot Blasting Machine

The BlastKing skew roll shot blasting machine is a fully automated system designed to remove rust and scale from many cylindrical parts: Pipe, tube, round bar, torsion bars, drill rod, re-bar, gas cylinders, etc.

The part is conveyed through the blast machine on a specially designed skew roll type material handling system.

Key Benefits and Features

Key Benefits for Skew Roll Shot Blasting Machine

- High cleaning capacity, short blasting time.

- Fully automatic processing for continuous production.

- Easy integration into entire or individual system elements into existing production line

- Accommodation of different tube lengths and diameters.

- Leading technology, outstanding performance.

- Low levels of wear due to a high manganesse lining of blasting chamber.

- Compact modular deign.

- Multiple blast module options for high volume production.

Features for Skew Roll Shot Blasting Machine

- System includes ORICA blasting turbines to ensure optimum performance in all requirements.

- Available with one, two or more blast turbines, depending on the application and cleaning rate.

- High capacity abrasive recycling to recover and clean the abrasive.

- Optional rotary screen separator for tramp metal removal.

- Machines are available for parts with diameters from 1/4” up to 24”.

- Wear resistant Long lifespan cast premium alloy rolls.

- Variable speed skew roll conveyor.

- Entry and exit vestibule seals are sized for different ranges of diameters.

- High efficiency dust collectors are sized specifically for the machine.

Skrew Roll Shot Blasting Machine

The BlastKing skew roll shot blasting machine is a fully automated system designed to remove rust and scale from many cylindrical parts:

- Pipes

- Tubes

- Round bars

- Torsion bars

- Drill rods

- Re-bars

- Gas cylinders, etc.

The part is conveyed through the blast machine on a specially designed skew roll type material handling system. An extensive range of high production blast cabinets are available to handle a wide variety of work sizes at variable cleaning speeds.

BlastKing products include standard and customized systems to meet individual customer requirements.

References to Skew Roll Shot Blasting Machine

Shot Blasting Cabinet

As with all BlastKing Skew Roll Shot Blasting Machines the shot blasting cabinet liner is manufactured completely from high manganese. High manganese has a property which is hard enough to deal with the shot blasting from 35HRC to more than 60HRC. They are attached from the outside and are easy to replace. When aggressive shot is used, additional lining of high manganese, tool steel or cast material can be provided.To avoid shot leakage, several rubber layers or curtains are fitted in areas of heavy wear. These are mounted in a V-Track and are easy to replace.

BlastKing ORICA Blast Turbine

BlastKing group have the patented technology of the direct drive blasting turbine which motor power from 22kw to 75kw.

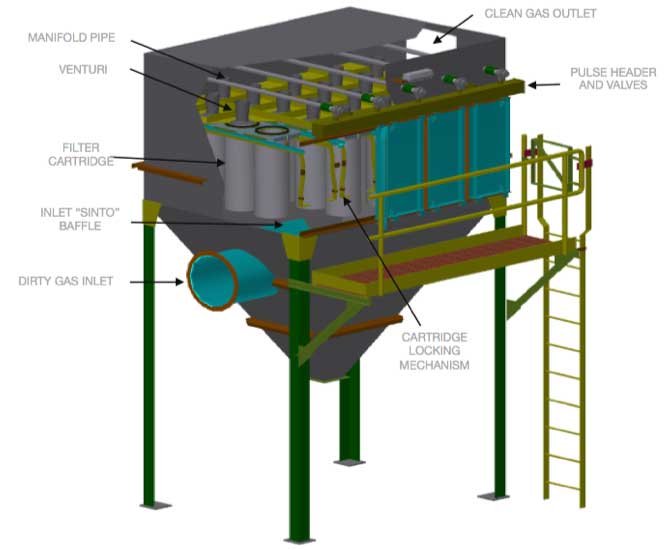

Cartridge Filter Unit

Each BlastKing machine is equipped with multiple cartridge filters. Above all these filters are necessary to remove any impurities from the air used to blast resulting in a more even, direct, and effective blast.

To sum up, benefits experienced with the BlastKing’ cartridge filters:

- Large distance between folds in each cartridge filter leads to precise cleaning and better air pressure.

- Most importantly, the impact separator within the cartridge filter unit ensures that the broken down fines are separated (which protects the filter cartridge against unnecessary wear).

- And easy exchange of cartridge filters.

- Further, correct contact pressure.

- Moreover, low compressed air consumption.

- In addition, constant cleaning, from top to bottom, due to conical design of the cartridge filter.

Installation, After-sale, Training & Safety

BlastKing Provide turnkey installation for the shot blaster. But DIY installation by customer is also available according to the comprehensive documents, videos and drawings which provide by BlastKing. Furthermore, our engieers team also can provide real-time installation guidance.

The successful implementation of any blasting equipment is based upon the total commitment and dedication to the process. Thus BlastKing’s field technicians are involved in the installation and training of the programmer and operator at the customer’s site or at BlastKing’s training facility. At the same time, BlastKing has developed a complete program of maintenance training seminars. Above all, these are just scheduled not only for new users but also for existing users. In short, This structure is ideal for customers to send new employees so they can become more conversant with all BlastKing’s equipment.

Guarantee time of shot blasting machine will be one to five years. Most importantly, technical support will be during the whole blasting machine life. In addition, consumable spare parts will be supplied periodically.

All the equipment from BlastKing is conformity with CE&BV standard, and our factory have ISO9001, ISO14001 certification.

General emergency stop button is on all the BlastKing’s control panel. And sub emergency stop buttons are on conveyor systems. Moreover, detectors on the blast wheel covers, blasting chamber windows, elevators, separators will protect safety of the operators. Further, dust collection unit of shot blast machine dust emisssions is under 3mg/m3 which also bring dust free working environment.