Applications

The wheel rims shot blasting machine are specially designed for blast processing wheel hubs, alloy wheels, wheel rims, etc.

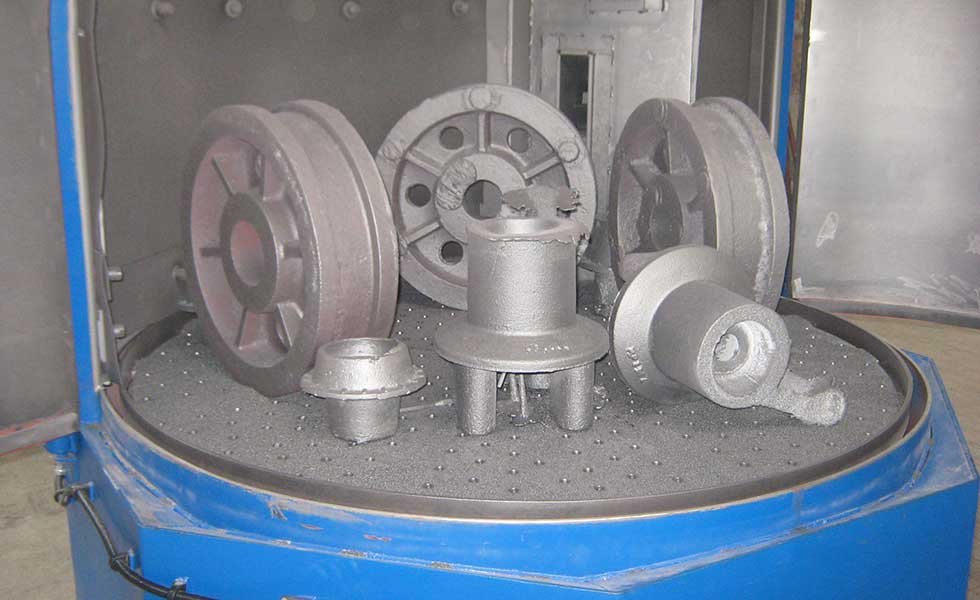

First of all, the shotblasting process is for treating car and motorcycle wheel rim surfaces, which aim is to make them homogeneous or removing any residual burrs due to the casting process.

Further more, the shotblasting process is for removing the layers of casting earth following the casting process. In short, the mass of earth that contains the castings is crushed and separated from the pieces by the impact of the shot and even the slightest slag on the pieces is removed by abrasion.

In addition, the shotblast processing is for removing old paint from wheel hubs from heavy machinery.

Wheel Rims Shot Blasting Machine Introduction

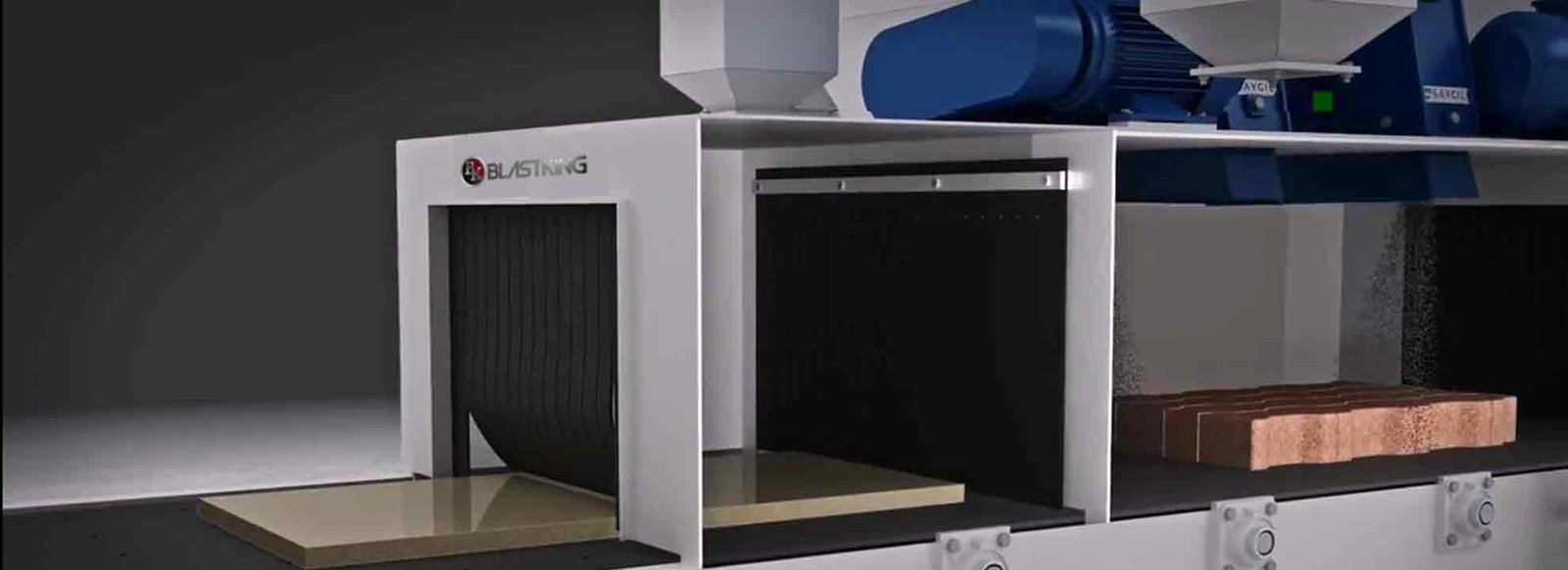

The BlastKing’s overhead rail conveyor wheel shot blasting machine can reach to blast cleaning of approximately 320 truck rims per 8-hour shift. But for wheel repair service companies using the spinner hanger and rotary table type shot blasting machine will be enough to do their job. The roller conveyor and mesh belt conveyor shot blasting machine for wheel rims are pass through type shot blasting machines, they can be easily integrated into the existing production line, also the free sand blaster or blast room are available for blast cleaning and peening wheel rims.

All In-house Manufacturing

Built & Assembled in China

Machine Customization

Industry-Leading Warranties

Whatever your production requirements or budget constraints, BlastKing always has a wheel and rim blast cleaning system for you.

References to Wheel Rims Shot Blasting Machine

BlastKing ORICA Blast Turbine

BlastKing group have the patented technology of the direct drive blasting turbine which motor power from 22kw to 75kw.

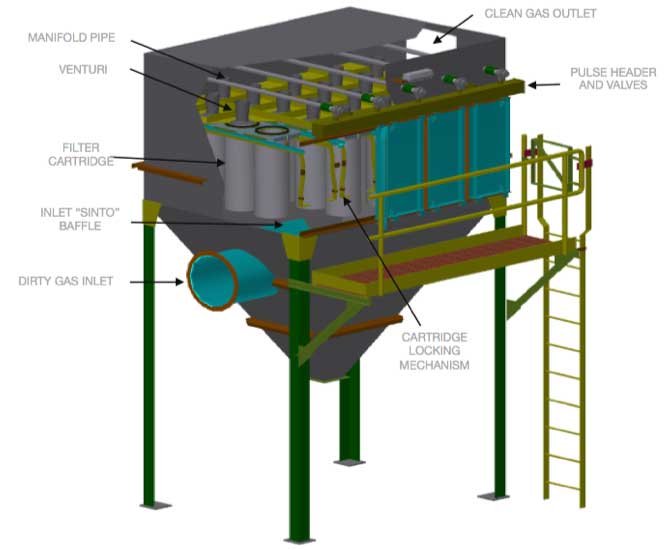

Cartridge Filter Unit

Each BlastKing machine is equipped with multiple cartridge filters. Above all these filters are necessary to remove any impurities from the air used to blast resulting in a more even, direct, and effective blast.

To sum up, benefits experienced with the BlastKing’ cartridge filters:

- Large distance between folds in each cartridge filter leads to precise cleaning and better air pressure.

- Most importantly, the impact separator within the cartridge filter unit ensures that the broken down fines are separated (which protects the filter cartridge against unnecessary wear).

- And easy exchange of cartridge filters.

- Further, correct contact pressure.

- Moreover, low compressed air consumption.

- In addition, constant cleaning, from top to bottom, due to conical design of the cartridge filter.

Installation, Post-sale, Training & Safety

BlastKing Provide turnkey installation for the shot blaster. But DIY installation by customer is also available according to the comprehensive documents, videos and drawings which provide by BlastKing. Furthermore, our engieers team also can provide real-time installation guidance.

The successful implementation of any blasting equipment is based upon the total commitment and dedication to the process. Thus BlastKing’s field technicians are involved in the installation and training of the programmer and operator at the customer’s site or at BlastKing’s training facility. At the same time, BlastKing has developed a complete program of maintenance training seminars. Above all, these are just scheduled not only for new users but also for existing users. In short, This structure is ideal for customers to send new employees so they can become more conversant with all BlastKing’s equipment.

Guarantee time of shot blasting machine will be one to five years. Most importantly, technical support will be during the whole blasting machine life. In addition, consumable spare parts will be supplied periodically.

All the equipment from BlastKing is conformity with CE&BV standard, and our factory have ISO9001, ISO14001 certification.

General emergency stop button is on all the BlastKing’s control panel. And sub emergency stop buttons are on conveyor systems. Moreover, detectors on the blast wheel covers, blasting chamber windows, elevators, separators will protect safety of the operators. Further, dust collection unit of shot blast machine dust emisssions is under 3mg/m3 which also bring dust free working environment.

FAQ

Have questions or need help? We’re here to help you. Whether you are inquiring about a quote/order, seeking sales or site assistance, technical support or for general inquiries you’ve come to the right place. If you wish to contact BlastKing Group by email, please fill out the requested information below in order for us to better serve you.